If your car’s air conditioning isn’t cooling as it should, the air compressor could be the culprit. This critical component pressurizes the refrigerant in your AC system, keeping you cool on those hot summer drives. Replacing a faulty air compressor yourself can save you money and give you a sense of accomplishment. Here’s a comprehensive guide to help you through the process.

Importance of the Car’s Air Compressor

Why is the air compressor important?

Your car’s air compressor is essential for the efficient operation of your vehicle’s air conditioning system. It compresses the refrigerant, turning it from a gas into a liquid and allowing it to circulate through the system, providing you with cool air.

Signs of a failing air compressor include:

- Unusual noises when the AC is on.

- Warm air blowing from the vents.

- AC system not engaging.

Addressing these issues promptly can prevent more extensive damage to your car’s AC system.

Tools and Materials Needed for the Replacement

Before you start, gather the following tools and materials. Proper preparation ensures a smoother process and enhances safety.

Tools Needed:

- Socket set and wrenches

- Screwdrivers (flathead and Phillips)

- Refrigerant recovery machine

- Vacuum pump

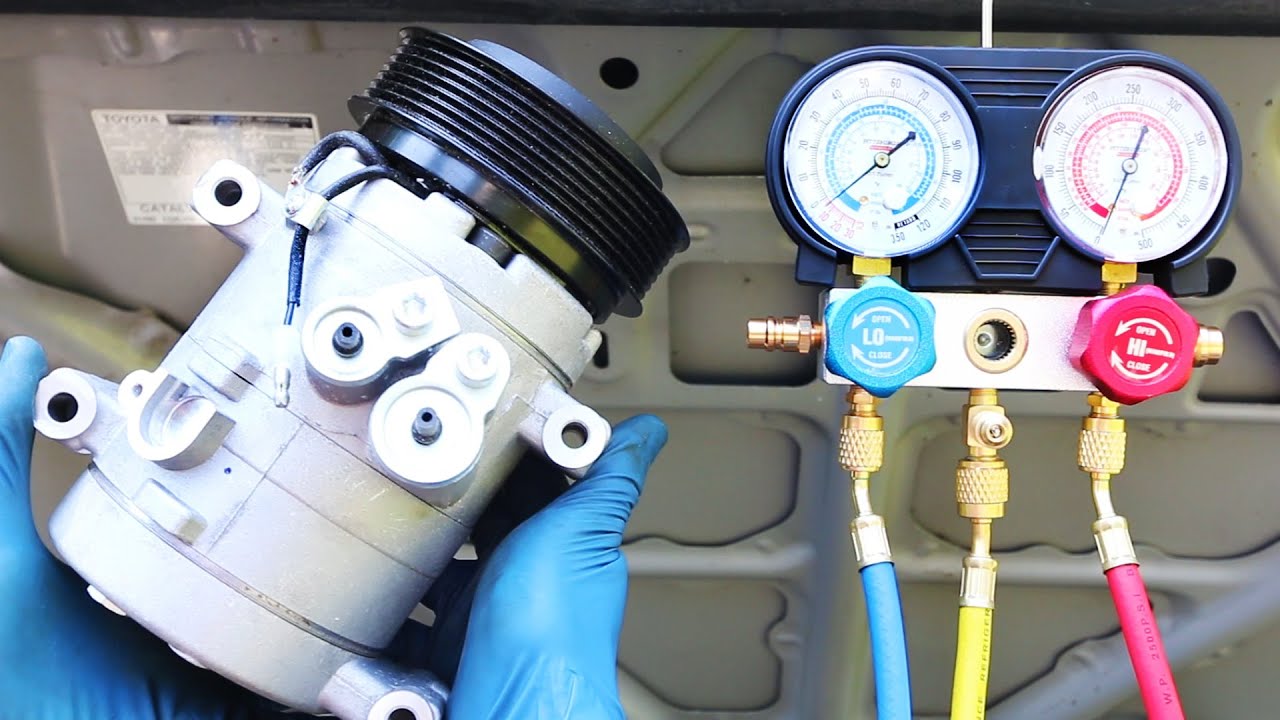

- Manifold gauge set

- Safety gear (gloves and safety goggles)

Materials Needed:

- New air compressor

- Refrigerant (specific to your car model)

- O-rings and seals

- Compressor oil (if not pre-filled)

Safety Gear:

- Gloves: Protect your hands from sharp edges and chemicals.

- Safety Goggles: Shield your eyes from harmful refrigerant exposure.

Step-by-Step Instructions on How to Safely Remove the Old Air Compressor

Step 1: Disconnect the Battery

- Safety Precaution: Always disconnect the battery to prevent electric shock.

- Locate the negative terminal and disconnect it using a wrench.

Step 2: Recover the Refrigerant

- Safety Precaution: Use a refrigerant recovery machine in a well-ventilated area to avoid inhaling refrigerant gas.

- Connect the recovery machine to the low and high service ports and follow the manufacturer’s instructions.

Step 3: Remove the Serpentine Belt

- Use a wrench to relieve tension from the belt tensioner and slide the belt off the compressor pulley.

Step 4: Disconnect the Electrical Connections

- Carefully unplug any electrical connectors attached to the compressor.

Step 5: Remove the Refrigerant Lines

- Safety Precaution: Wear gloves and safety goggles to protect against residual refrigerant.

- Use a wrench to disconnect the refrigerant lines from the compressor.

Step 6: Remove the Compressor Mounting Bolts

- Use a socket set to remove the bolts securing the compressor to the engine block.

- Carefully lift the old compressor out of the engine bay.

Guidance on How to Properly Install the New Air Compressor

Step 1: Position the New Compressor

- Place the new compressor in the same position as the old one and secure it with mounting bolts.

- Safety Precaution: Ensure all bolts are tightened to the manufacturer’s specifications to prevent leaks.

Step 2: Reconnect the Refrigerant Lines

- Attach the refrigerant lines to the new compressor, replacing any O-rings and seals to ensure a tight fit.

- Safety Precaution: Double-check all connections to prevent leaks.

Step 3: Reconnect Electrical Connections

- Plug in all electrical connectors.

Step 4: Reinstall the Serpentine Belt

- Loop the belt around the compressor pulley and release the tensioner to secure it in place.

Step 5: Evacuate and Recharge the System

- Safety Precaution: Use a vacuum pump and manifold gauge set to evacuate the system before recharging it with the correct type and amount of refrigerant.

- Follow the instructions on your AC recharge kit.

Replacing a car AC compressor can be a complex task that requires careful consideration of several components. In this article, we will discuss the various items that should be replaced when replacing a car AC compressor.

New Compressor

The most obvious component that needs to be replaced is the AC compressor itself. It is essential to find a compatible compressor for your specific vehicle make and model. Make sure to purchase a high-quality compressor to ensure optimal performance and durability.

Basic Hand Tools

To successfully replace the AC compressor, you will need basic hand tools such as wrenches, screwdrivers, a ratchet, and pliers. These tools will aid in the removal of the old compressor and the installation of the new one.

Refrigerant Recovery Tank

A refrigerant recovery tank is required to safely recover the refrigerant from the AC system before replacing the compressor. This ensures that no refrigerant is released into the environment, as it is harmful to the ozone layer.

Equipment for Recover and Charge System

In addition to a refrigerant recovery tank, you will need specific equipment to properly recover and charge the AC system. This includes a vacuum pump and a manifold gauge set. These tools are essential for the proper evacuation and charging of the system after compressor replacement.

Refrigerant

A sufficient amount of refrigerant is needed to recharge the AC system after replacing the compressor. Make sure to use the appropriate type and quantity of refrigerant recommended by the manufacturer for your vehicle.

Torch

A torch may be required to heat and loosen stubborn fittings during the removal of the old compressor. This will facilitate a smooth and efficient replacement process.

Other Considerations

While replacing the AC compressor, it is also advisable to inspect and potentially replace other components to ensure optimal system performance. Some components to consider replacing include:

- Seals: Replace any damaged or worn seals to prevent refrigerant leaks.

- Accumulator: Consider replacing the accumulator to reduce the risk of further issues.

- Orifice Tube or TXV: Depending on your vehicle’s system, replace either the orifice tube or the thermal expansion valve (TXV) for optimal performance.

- Dryer: Most compressor warranties require replacing the dryer, as it contains desiccant, which removes moisture from the system.

It is essential to follow the manufacturer’s guidelines and recommendations when replacing these additional components.

Post-Installation Checks

After replacing the AC compressor, it is important to perform post-installation checks to ensure optimal performance. These checks include:

- Vacuuming and Recharging: Properly vacuum and recharge the AC system to remove any air and moisture.

- Leak Inspection: Thoroughly inspect the system for any refrigerant leaks and address them accordingly.

- System Testing: Test the AC system to ensure that it is functioning properly and cooling the car as expected.

By following these steps and replacing all necessary components, you can ensure a successful AC compressor replacement that restores your vehicle’s cooling system to optimal condition.

Tips for Testing the New Compressor to Ensure Proper Functionality

Step 1: Reconnect the Battery

- Reattach the negative terminal to the battery.

Step 2: Start the Car and Turn On the AC

- Set the AC to the coldest setting and highest fan speed.

Step 3: Check for Functionality

- Listen for any unusual noises.

- Feel the air coming from the vents to ensure it’s cold.

Step 4: Inspect for Leaks

- Use a leak detector to check all connections and fittings for any signs of refrigerant leaks.

Safety Reminders and Notes on When to Seek Professional Help

- Read Your Car’s Manual: Each car is different. Always refer to your manual for specific instructions.

- When to Seek Help: If you encounter any issues or are unsure about any steps, it’s best to consult a professional mechanic to ensure your safety and the proper functioning of your AC system.

Conclusion

Replacing your car’s air compressor may seem daunting, but with the right tools and steps, you can accomplish this task efficiently. The benefits of a working air compressor cannot be overstated – it will keep your car cool, comfortable, and safe to drive.

Ready to tackle the job? Gather your tools, follow this guide, and enjoy the satisfaction of a job well done!

Frequently Asked Questions For What To Replace When Replacing Car Ac Compressor: Essential Guide

What Should Be Replaced When Replacing Ac Compressor?

When replacing the AC compressor, you should also replace the receiver/dryer and inspect system for leaks. This ensures proper cooling and optimal performance.

What To Do After Installing A New Ac Compressor?

After installing a new AC compressor, check for leaks, thoroughly vacuum and recharge the system for optimal cooling performance.

Can You Replace Just The Car Ac Compressor?

Yes, it’s possible to replace just the car AC compressor, but ensure the refrigerant lines are disconnected.

Do You Have To Replace Dryer When Replacing Ac Compressor?

When replacing the AC compressor, it’s recommended to also replace the dryer to ensure optimal performance and warranty compliance. The dryer contains desiccant to eliminate trapped moisture in the system, crucial for AC efficiency. It’s an essential practice for a thorough AC system maintenance.