Turning vanes in HVAC ductwork help direct airflow smoothly, reducing resistance and turbulence for efficient air circulation. These sheet metal devices are essential components in HVAC systems to ensure optimal performance and airflow balance.

Without turning vanes, the system may experience airflow deficiencies and decreased efficiency, leading to potential system failures. Properly installed turning vanes play a crucial role in maintaining the functionality and effectiveness of HVAC systems by ensuring a consistent and controlled airflow pattern throughout the ductwork.

For businesses and homeowners in Austin, Texas, turning vanes are indispensable elements in achieving proper air distribution and ventilation in their HVAC systems.

Importance Of Turning Vanes In Hvac Systems

Enhancing Airflow Efficiency

Turning vanes play a crucial role in HVAC systems by improving airflow efficiency.

Preventing Airflow Restrictions

Turning vanes help prevent airflow restrictions, ensuring smooth air circulation.

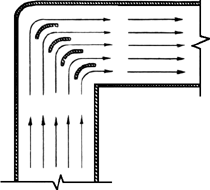

Credit: buildingengineer.wordpress.com

Installation And Application Of Turning Vanes

Turning vanes in HVAC systems assist in directing airflow smoothly by reducing resistance and turbulence at duct directional changes. They are installed strategically at elbows to ensure efficient air distribution. Proper application of turning vanes ensures optimal airflow and prevents system failure.

Placement In Duct Systems

Turning vanes are typically installed in HVAC duct systems where there is a change in airflow direction, such as at elbows and tees. This placement helps to reduce resistance and turbulence in the ductwork.

Selection And Sizing Considerations

When selecting turning vanes, it is crucial to consider the size of the ductwork and the airflow requirements. Proper sizing ensures optimal performance and efficiency in directing the airflow smoothly.

Factors to consider:

- Size of the ductwork

- Airflow requirements

Proper selection and sizing of turning vanes play a significant role in improving the overall airflow efficiency and reducing energy consumption in HVAC systems.

Types And Designs Of Turning Vanes

Turning vanes, also known as guide vanes, are an integral part of HVAC systems, assisting in controlling airflow and reducing turbulence. Different types of turning vanes are available to cater to specific airflow requirements and noise reduction needs. Let’s explore the various designs and types of turning vanes.

Standard Sheet Metal Turning Vanes

Standard sheet metal turning vanes are commonly used in HVAC systems to redirect air smoothly when there is a change in direction in the ductwork. They are made of durable and rigid sheet metal, carefully designed to minimize resistance and turbulence while ensuring efficient airflow.

Acoustical And Noise-reducing Turning Vanes

For environments where noise reduction is a priority, acoustical and noise-reducing turning vanes are the ideal choice. These turning vanes are equipped with specialized materials and designs that effectively dampen sound and minimize the transmission of noise, maintaining a comfortable and quiet indoor environment.

Credit: blog.mestekmachinery.com

Impact Of Turning Vanes On Hvac Performance

Turning vanes in HVAC systems play a vital role in optimizing airflow and enhancing overall performance. By reducing resistance and turbulence, and through the optimization of equipment functionality, turning vanes ensure efficient and smooth airflow, resulting in improved HVAC performance.

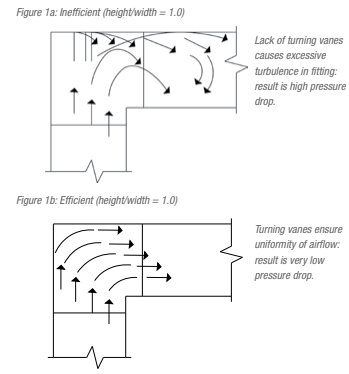

Reduction Of Resistance And Turbulence

One significant impact of turning vanes on HVAC performance is the reduction of resistance and turbulence within the system. When air changes direction abruptly in a duct, it causes resistance and turbulence, leading to pressure drop and inefficient airflow. Turning vanes act as streamline guides, directing air smoothly and gradually through bends and transitions.

By strategically installing turning vanes at specific points in the ductwork, HVAC systems can effectively minimize resistance and turbulence. This reduction leads to various benefits:

- Improved energy efficiency as there is less energy wasted in overcoming resistance and friction.

- Enhanced airflow balance throughout the system, ensuring consistent and even distribution of conditioned air.

- Reduced noise caused by turbulence, resulting in a more comfortable and peaceful indoor environment.

Optimization Of Equipment Functionality

Turning vanes also play a crucial role in optimizing the functionality of HVAC equipment. By facilitating smoother airflow, these devices ensure that HVAC systems operate more effectively and efficiently.

When airflow encounters obstacles such as sharp bends or transitions without turning vanes, it can lead to increased pressure loss, decreased equipment performance, and ultimately, higher energy consumption. Turning vanes help prevent these issues by allowing air to flow more freely and evenly through the system.

With optimized airflow, HVAC equipment benefits in several ways:

- Increased operational efficiency, resulting in reduced energy consumption and lower utility costs.

- Extended equipment lifespan due to reduced strain and wear caused by inefficient airflow.

- Enhanced performance capabilities, providing effective temperature control and better indoor air quality.

Therefore, investing in well-designed turning vanes is a cost-effective way to improve HVAC performance, reduce energy waste, and ensure the longevity of equipment.

Factors Affecting Cost And Efficiency Of Turning Vanes

Ensuring optimal efficiency and cost-effectiveness of turning vanes in HVAC systems entails proper installation at key duct junctures. Factors influencing the effectiveness include airflow velocity, duct size, and the positioning of turning vanes within the system. Properly placed turning vanes promote smoother airflow direction changes for enhanced system performance.

Evaluation Of Cost And Roi

When it comes to evaluating the cost and efficiency of turning vanes in HVAC systems, several factors need to be taken into consideration. The cost of turning vanes can vary depending on the materials used, the size of the ductwork, and the complexity of the system. Additionally, the return on investment (ROI) is an important factor to consider when deciding whether to invest in turning vanes. One of the key advantages of turning vanes is their ability to improve the airflow within the ductwork. By directing the airflow smoothly around corners and changes in direction, turning vanes reduce resistance and turbulence, resulting in increased efficiency. This improved efficiency can lead to energy savings and lower operating costs in the long run. To evaluate the cost and ROI of turning vanes, it is essential to consider the initial investment required for installation. This includes the cost of purchasing the turning vanes themselves, as well as any additional labor or equipment needed for installation. However, it’s important to note that the benefits of reduced energy consumption and improved airflow can offset these initial costs over time. To calculate the ROI of turning vanes, factors such as energy savings, reduced maintenance costs, and improved system performance should be considered. These factors can contribute to long-term cost savings and improved efficiency, making turning vanes a worthwhile investment for many HVAC systems.Comparative Analysis Of Turning Vane Designs

When comparing different turning vane designs, it is crucial to consider their impact on both cost and efficiency. Different turning vane designs can vary in terms of materials used, installation requirements, and overall performance. One common type of turning vane design is the hollow turning vane and vane rail. This design is specifically engineered to redirect the air through elbows and tees in the ductwork, minimizing resistance and turbulence. The hollow design helps to reduce weight and improve airflow, resulting in improved system efficiency. Another design option is the solid turning vane. Solid turning vanes are typically made from durable materials such as sheet metal and provide excellent support and stability to the airflow. These vanes are often used in larger HVAC systems where there is a higher volume of air movement. When comparing turning vane designs, it’s important to consider the specific requirements of the HVAC system in question. Factors such as the size and layout of the ductwork, air volume, and pressure drop limitations should all be taken into account. Additionally, consulting with HVAC professionals or manufacturers can provide valuable insights and recommendations on which turning vane design would best suit the system’s needs. In conclusion, factors such as cost, ROI, and comparative analysis of turning vane designs are crucial when considering the implementation of turning vanes in HVAC systems. By carefully evaluating these factors, HVAC professionals can make informed decisions that result in improved system efficiency, reduced energy consumption, and long-term cost savings.

Credit: www.sheetmetaljournal.com

Frequently Asked Questions Of Turning Vanes Hvac

What Is The Purpose Of Turning Vanes?

Turning vanes assist airflow by creating a smoother change in direction, reducing impact and force transfer.

Do Return Ducts Need Turning Vanes?

Yes, return ducts may benefit from turning vanes to promote smooth airflow and prevent airflow deficiencies. Enlarging the ducts and adding turning vanes to the elbows can facilitate better performance in HVAC systems.

Where Are Turning Vanes Installed In A Duct?

Turning vanes are installed in a duct to assist airflow in smoothly changing direction. They reduce resistance and turbulence, resulting in less force transferred and improved airflow.

What Is A Turning Vane In The Elbow?

Turning vanes are sheet metal devices installed inside HVAC ducts to guide airflow smoothly when there is a change in direction. They help reduce resistance and turbulence, resulting in a more gradual change in airflow direction and less force transferred.

Turning vanes are essential in promoting efficient airflow in HVAC systems.

Conclusion

In today’s blog, we’ve delved into the importance of turning vanes in HVAC systems. From enhancing airflow and reducing turbulence to improving system efficiency, turning vanes play a crucial role. Understanding their significance and proper installation can lead to a more effective HVAC system.

To ensure optimal performance, incorporating turning vanes is a decision that shouldn’t be overlooked.