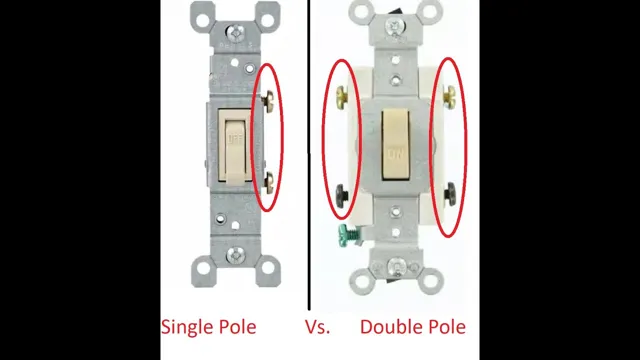

As an electrician or homeowner, you may have come across the terms “single pole contactor” and “double pole contactor”. But what do these terms mean, and what’s the difference between them? Both single pole and double pole contactors are used to control the amount of electricity flowing through a circuit, but they differ in how many circuits they control. A single pole contactor controls just one circuit, while a double pole contactor controls two.

This means that a double pole contactor is capable of cutting off power to both the hot and neutral wires of a circuit, while a single pole contactor only cuts off power to the hot wire. So why does this matter? Well, in certain situations, it may be necessary to cut off power to both the hot and neutral wires, such as when working with large appliances or HVAC equipment. In these cases, a double pole contactor would be the safer choice.

However, for smaller circuits such as lighting or low-power appliances, a single pole contactor may be perfectly sufficient. Ultimately, the choice between a single pole and double pole contactor comes down to the specific needs of your electrical system.

Definitions

When it comes to electrical systems, it’s essential to understand the difference between single pole and double pole contactors. A single pole contactor is a switch that controls one circuit, while a double pole contactor controls two circuits simultaneously. The key difference between the two is that double pole contactors provide a higher level of safety and protection, especially when dealing with large electrical loads.

This is because they effectively break both the live and neutral wires, disconnecting the electrical supply entirely and preventing any accidental electric shocks. However, single pole contactors are commonly used in smaller circuits, such as lighting systems or small appliances, where the risk of electrical shock is minimal. Ultimately, the type of contactor that you choose will vary depending on the electrical system and the size of the load being used.

It’s important to consult with an experienced electrician to ensure that the correct type of contactor is selected for your particular application.

Single pole contactor:

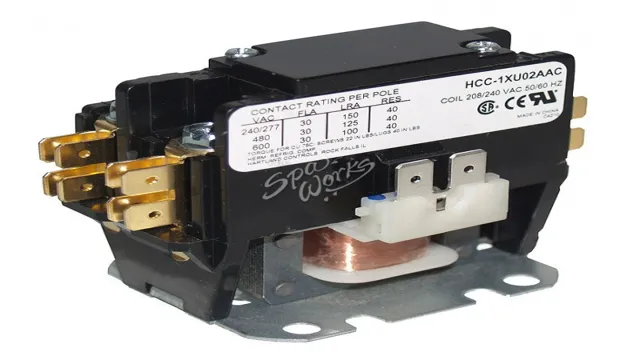

A single pole contactor is an electromechanical switch used for controlling an electrical circuit that requires a high current rating. The term ‘single pole’ refers to the number of contacts or poles the switch has, only one. This means that the contactor can only connect and disconnect one circuit at a time.

The contactor is composed of a coil, contacts, and various other components, which determine its rating, size, and application. The coil is an electromagnet that, upon being energized, generates a magnetic field that attracts the contacts to complete the circuit. The contacts are responsible for carrying the current required by the load and are typically made of materials that can withstand the high voltage and current requirements.

The single pole contactor is commonly used in HVAC systems, lighting control, and other industrial applications requiring high-current switching.

Double pole contactor:

A double pole contactor, also commonly known as a DP contactor, is an electrical switch that controls the flow of electric current in two separate circuits simultaneously. This type of contactor is typically used in high-voltage applications, such as electric motors, heating elements and air conditioning systems, where two separate power sources are required. The term “double pole” refers to the fact that the contactor has two separate poles, or switches, which operate independently of each other.

This means that when one pole is closed, the other remains open, and vice versa. Double pole contactors are often used in industrial and commercial applications, where reliability and safety are of utmost importance. They are designed to handle large amounts of electrical current and are typically made with high-quality materials that can withstand harsh conditions.

If you require an electrical switch that can handle multiple circuits at once, a double pole contactor may be the best choice for you.

Functions

When it comes to electrical components, choosing the right one can be confusing. One area of confusion for many people is the choice between a single pole contactor and a double pole contactor. So, what’s the difference? Simply put, single pole contactors control one circuit, while double pole contactors control two separate circuits.

In other words, a double pole contactor allows for more control and protection, as it has an extra set of contacts. This can be important in certain situations, such as when dealing with high-voltage equipment or machinery that requires more than one power source. However, a single pole contactor can be sufficient for smaller, less complex applications.

Ultimately, the choice between a single pole and double pole contactor depends on the specific needs of your project or system.

Single pole contactor function:

A single pole contactor is an electrical switch that consists of one set of contacts, a coil, and an electromagnet. The coil is connected to a power source, and when energized, it creates a magnetic field that pulls the contacts together, allowing electrical current to flow through the device. The primary function of a single pole contactor is to control the flow of electrical power to a specific circuit or device.

For example, in HVAC systems, single pole contactors are often used to control the power to a compressor or fan motor. By turning the contactor on and off, the system can regulate its output and maintain specific temperature settings. Additionally, single pole contactors can be used in industrial settings to turn on and off machines or other equipment.

One of the unique features of single pole contactors is that they are designed to operate independently. This means that each contactor can be controlled separately, allowing for greater flexibility and customization in electrical systems. Additionally, single pole contactors have a compact design that allows them to fit into a small space.

In conclusion, single pole contactors are essential components in electrical systems that provide on/off control for circuits and devices. They are dependable, efficient, and flexible devices that contribute to the overall functionality of a wide range of electrical applications.

Double pole contactor function:

A double pole contactor is an electro-mechanical component used to control electrical circuits that require high power consumption, including HVAC units, lighting fixtures, and industrial machinery. The function of the double pole contactor is to open and close the electrical circuit, allowing the current flow to reach the connected devices. The double pole contactor is composed of two sets of contacts that are activated through a magnetic field created by a coil.

When activated, the magnetic field pulls down a movable armature to connect the two sets of contacts, thus allowing the current flow. The double pole contactor feature provides additional security to the circuit, as it ensures both the positive and negative poles are disrupted. In case of any electrical malfunction, the double pole contactor protects the circuit by preventing further electrical damage.

Therefore, a double pole contactor is an essential component in ensuring the safe and efficient functioning of electrical circuits requiring high power consumption.

Applications

When it comes to choosing between a single pole contactor and a double pole contactor, there are several important factors to consider. Single pole contactors are typically used in low voltage applications, where they can effectively switch on and off one phase of an electrical circuit. They are also generally less expensive and easier to install than double pole contactors.

However, their use is limited to specific applications where only one phase needs to be switched on or off. Double pole contactors, on the other hand, are more versatile and can control two phases simultaneously. They are ideal for high voltage applications and offer additional safety features such as overloading protection and ground fault protection.

In summary, the choice between a single pole contactor and a double pole contactor ultimately depends on the electrical load and safety requirements of your application.

Single pole contactor applications:

Single pole contactors find numerous applications in the electrical industry due to their ability to start and control single-phase motors. These contactors are commonly used in HVAC, refrigeration, and lighting systems, as well as in industries such as food processing and packaging. Single pole contactors are used to switch on and off heating elements, compressors, and circulation motors.

They are also utilized in conveyor systems, pumps, and fans, where they are responsible for controlling the speed and direction of operation. Single pole contactors are known for their reliability, durability, and ability to handle high amps and voltage. They are an essential component in any electrical system that requires optimal performance and stability.

By incorporating single pole contactors in electrical systems, the system can perform efficiently, minimizing the risk of damage due to overloading or short-circuiting.

Double pole contactor applications:

When it comes to electrical systems, double pole contactors are essential for safety and efficiency in various applications. One common use for double pole contactors is in air conditioning units, where they help to control the flow of power to the compressor motor. Another application of double pole contactors is in lighting systems, where they enable the easy and safe control of multiple lighting circuits from a central location.

They are also used in heating systems, elevators, and industrial machines, among other things. Double pole contactors are designed to interrupt the circuit in both power lines simultaneously, ensuring complete isolation of the electrical system in case of emergency. This is crucial for safe and reliable operation, making them a go-to choice for many different applications in the electrical industry.

Comparison

When it comes to controlling electrical circuits, single pole contactors and double pole contactors are two popular options. The main difference between them is the number of poles or connection points available. Single pole contactors have only one pole, allowing them to control one circuit at a time.

Double pole contactors, on the other hand, have two poles, which means they can switch off two circuits at the same time. This extra feature can be particularly useful in situations where you need to isolate multiple circuits for safety reasons or to help prevent electrical interference. However, double pole contactors are typically larger and more expensive than their single pole counterparts.

With all that said, the choice between single pole or double pole contactors ultimately depends on your specific needs and the electrical setup of your application.

Advantages and disadvantages of single pole contactor:

Advantages and disadvantages of single pole contactor are crucial to understand before using them in electrical systems. The primary advantage of using a single pole contactor is that it is cost-effective and requires less space. These devices work efficiently and can control the load of up to 120V.

Also, the single-pole contactors are simple to install and have fewer wires, making them easier to manage. However, they also have some disadvantages to consider. For instance, they cannot handle high horsepower loads and may experience arcing, making them less reliable.

Additionally, single-pole contactors may cause operational delays as they only turn off one leg of the circuit and not both, which could potentially lead to equipment damage. Therefore, it is essential to consult with a certified electrician to assess the system requirements before using single pole contactors. In conclusion, while single pole contactors offer cost-effective and space-saving benefits, their limitations and drawbacks must be taken into account when selecting and installing them in electrical systems.

Advantages and disadvantages of double pole contactor:

Double pole contactors have their own advantages and disadvantages when compared to other types of contactors available in the market. The biggest advantage of a double pole contactor is that it can break the circuit at two different points, providing an extra layer of safety. This ensures that the power supply is completely cut off, preventing any electrical accidents that could cause damage to the equipment or harm to the user.

However, the downside to this is that double pole contactors are bulkier and more expensive compared to single pole contactors. Another disadvantage of double pole contactors is that they require more space to install due to their larger size. This can be a challenge when working with existing electrical systems that have limited space.

On the other hand, the additional safety features provided by double pole contactors make them a preferred choice for use in HVAC units and large electrical systems where safety is of utmost importance. In summary, the double pole contactor offers an extra layer of safety and is the preferred choice for electrical systems where safety is critical. However, they are bulkier and more expensive than other types of contactors, which can be a drawback in some situations.

Nevertheless, it is essential to consider the advantages and disadvantages of double pole contactors before choosing the right one for your electrical system.

Conclusion

In the world of electrical components, the decision to choose a single pole or double pole contactor can make all the difference. Single pole may seem like the flashy, solo player, but double pole brings in the backup for added security. Ultimately, it’s best to weigh the needs of the system and choose the contactor that will keep everything running smoothly, without any unexpected surprises.

“

FAQs

What is a single pole contactor?

A single pole contactor is an electrical switch that controls a single electrical circuit.

What is a double pole contactor?

A double pole contactor is an electrical switch that controls two separate electrical circuits.

What is the difference between a single pole and double pole contactor?

The main difference between a single pole and double pole contactor is that a single pole only controls one electrical circuit, while a double pole controls two. This means that double pole contactors are often used for higher voltage or more complex electrical systems.

When should I use a single pole contactor?

Single pole contactors are most commonly used in low voltage lighting systems, air conditioning systems, and other small electrical systems.

When should I use a double pole contactor?

Double pole contactors are typically used in industrial or commercial electrical systems that require higher voltage or more complex control. They are commonly used for controlling motors, pumps, and other heavy-duty equipment.

Can a single pole contactor be upgraded to a double pole contactor?

In most cases, it is possible to upgrade a single pole contactor to a double pole contactor by simply replacing the old switch with a new one. However, this may require some rewiring and other modifications to the electrical system, so it is best to consult with a qualified electrician before making any changes.