Featured image for install central air conditioner

Image source: cdn.howmuch.net

Installing a central air conditioner requires careful planning, proper sizing, and professional expertise to ensure optimal performance and energy efficiency. This guide walks you through every step—from selecting the right unit and preparing your home’s ductwork to safe electrical connections and system testing—so you can confidently install central air conditioner systems with precision. Whether you’re a seasoned DIYer or hiring a pro, understanding the process helps avoid costly mistakes and maximizes long-term comfort.

Key Takeaways

- Plan carefully: Assess your home’s size and layout before buying a unit.

- Hire professionals: Always use licensed HVAC technicians for safe, code-compliant installation.

- Choose correctly: Select a properly sized AC unit to maximize efficiency and comfort.

- Seal ducts: Prevent energy loss by sealing and insulating all ductwork thoroughly.

- Test system: Run performance tests after installation to verify optimal operation.

- Maintain regularly: Schedule annual tune-ups to extend lifespan and efficiency.

📑 Table of Contents

- How to Install Central Air Conditioner: A Complete Guide

- 1. Assess Your Home and Plan the Installation

- 2. Gather Tools, Permits, and Equipment

- 3. Prepare the Indoor and Outdoor Spaces

- 4. Install the Refrigerant Lines and Electrical Wiring

- 5. Connect, Charge, and Test the System

- 6. Final Touches and Maintenance Tips

How to Install Central Air Conditioner: A Complete Guide

Imagine this: It’s the middle of July, the sun is blazing, and your old window unit just gave up the ghost. You’re sweating through your shirt, and the idea of another summer without cool air is unbearable. That’s when the thought hits you—maybe it’s time to install a central air conditioner.

Installing a central air conditioner isn’t just about beating the heat. It’s about comfort, air quality, and long-term energy savings. Unlike noisy window units or portable ACs, central air delivers consistent, quiet cooling throughout your entire home. But the process can feel overwhelming—especially if you’re a first-timer. You might be wondering: Can I do this myself? What equipment do I need? And how much will it really cost? Don’t worry. This guide walks you through every step of how to install central air conditioner, from planning and permits to final testing. Whether you’re a DIY enthusiast or just want to understand the process before hiring a pro, this guide has your back.

1. Assess Your Home and Plan the Installation

Before you even think about buying equipment, you need to take a hard look at your home’s layout, existing HVAC system, and energy needs. A successful central air installation starts with smart planning—not guesswork.

Visual guide about install central air conditioner

Image source: homesthetics.net

Check Your Current HVAC Setup

Most central air conditioners work with a forced-air furnace or heat pump. If your home already has ductwork and a furnace, you’re in a good position. But if you’re starting from scratch—say, in an older home with radiators or baseboard heating—you’ll need to install ductwork, which adds time and cost.

- Existing ductwork? Inspect it for leaks, insulation, and proper sizing. Ducts that are too small or poorly sealed can reduce efficiency by up to 30%.

- No ducts? You’ll need to plan a duct installation. This is a major project, often requiring walls to be opened, but it’s doable with careful planning.

- Furnace compatibility? Your furnace must be able to handle the airflow demands of the AC unit. Most modern furnaces are compatible, but older models may need upgrades.

Tip: Use a flashlight and camera to crawl into your attic or basement and take photos of your current system. This helps contractors (or you) assess what’s already in place.

Calculate the Right AC Size (Tonnage)

One of the biggest mistakes people make is choosing the wrong size unit. Too small, and it won’t cool your home. Too big, and it will short-cycle (turn on and off too quickly), wasting energy and wearing out parts.

AC units are measured in “tons”—1 ton = 12,000 BTUs of cooling per hour. To find the right size:

- Measure your home’s square footage (length × width).

- Use the general rule: 1 ton per 400–600 sq ft, depending on climate and insulation.

- Adjust for sun exposure, ceiling height, number of windows, and insulation quality.

For example: A 2,000 sq ft home in a hot, sunny climate with average insulation might need a 3.5- to 4-ton unit. In a milder area with good insulation, a 3-ton unit could suffice.

Pro tip: Hire an HVAC pro to do a Manual J load calculation. This detailed analysis considers all factors (windows, doors, duct loss, occupancy) and is the gold standard for sizing.

Choose the Right Location for the Outdoor Unit

The outdoor condenser unit needs a spot that’s:

- At least 12–24 inches from walls or shrubs (for airflow)

- On a level, solid pad (concrete or composite)

- Shaded if possible (but not under trees that shed leaves or debris)

- Close to the indoor air handler or furnace (to minimize refrigerant line length)

Avoid placing it in a noisy area (like near a bedroom window) or where it might collect snow, leaves, or water runoff.

2. Gather Tools, Permits, and Equipment

Now that you’ve planned the layout, it’s time to gather everything you’ll need. This step is critical—rushing out to buy tools or skipping permits can lead to costly mistakes.

Essential Tools for Installation

You’ll need a mix of basic hand tools and specialized HVAC equipment:

- Screwdrivers, wrenches, pliers

- Drill and bits

- Manifold gauge set (for refrigerant handling)

- Vacuum pump (for removing air and moisture from lines)

- Torque wrench (for tightening refrigerant connections)

- Tubing cutter and flaring tool

- Level and measuring tape

- Insulation tape and UV-resistant line cover (for refrigerant lines)

Note: If you’re not EPA 608 certified (required to handle refrigerant), do not attempt to charge the system yourself. Hire a licensed technician for this step.

Permits and Local Codes

Most municipalities require permits for HVAC installations. Skipping this step can result in fines or issues when selling your home.

- Contact your local building department to apply for a permit.

- They’ll likely require a site plan, equipment specs, and electrical load calculations.

- Inspections are usually required at key stages (ductwork, electrical, final).

Tip: Permit fees range from $100–$500, depending on your location. It’s a small price for peace of mind and code compliance.

Buy the Right Equipment

Choose a high-efficiency central air conditioner with a good SEER (Seasonal Energy Efficiency Ratio) rating. Look for:

- SEER 16+ for hot climates (higher = more efficient)

- ENERGY STAR certification

- Two-stage or variable-speed compressor (quieter, more efficient)

- Matched indoor and outdoor units (from the same manufacturer, same series)

For example: A Carrier Infinity 24VS (SEER 24) paired with a compatible air handler offers excellent efficiency and quiet operation.

3. Prepare the Indoor and Outdoor Spaces

With tools and permits in hand, it’s time to prep the installation sites. This phase ensures everything fits and functions safely.

Install or Modify Ductwork (If Needed)

If your ducts are old or leaky, now is the time to seal and insulate them. Use mastic sealant (not duct tape—it fails over time) and wrap with R-6 or R-8 insulation.

For new ducts:

- Design a layout that balances airflow to all rooms.

- Use rigid metal or insulated flex duct.

- Include a main trunk line with branches to each room.

- Add dampers to adjust airflow in different zones.

Example: A 3-ton system needs a 14″ × 18″ main trunk and 6″ round branch ducts to individual rooms.

Set the Outdoor Unit Pad

The condenser needs a stable, level base to prevent vibration and water pooling.

- Dig a 4–6″ deep area and fill with gravel for drainage.

- Place a pre-cast concrete pad or build one with rebar and concrete.

- Ensure it’s at least 3″ above ground to avoid snow or water.

Use a level to check—any tilt can affect refrigerant flow and compressor life.

Prepare the Indoor Air Handler

The air handler (or furnace) needs a dedicated electrical circuit and proper refrigerant line connections.

- Verify the furnace has a 240V power supply (most ACs need this).

- Install a disconnect switch near the air handler (required by code).

- Drill a hole through the wall for refrigerant and electrical lines (usually 2–3″ diameter).

Tip: Wrap the hole with a rubber grommet to prevent wire chafing and air leaks.

4. Install the Refrigerant Lines and Electrical Wiring

This is where things get technical. Refrigerant lines carry the cooling medium between the indoor and outdoor units, while electrical wiring powers the system and thermostat.

Run the Refrigerant Lines

Most systems use two copper lines:

- Liquid line (smaller): Carries high-pressure liquid refrigerant to the indoor coil.

- Suction line (larger): Returns low-pressure vapor to the compressor.

Steps to install:

- Cut and flare the copper tubing to length.

- Run the lines through the pre-drilled hole, keeping them as straight and short as possible (max 50–75 ft).

- Insulate both lines with foam tubing (prevents condensation and energy loss).

- Support the lines every 3–5 ft with straps or hangers.

Warning: Never bend copper lines too tightly—this restricts refrigerant flow and reduces efficiency.

Connect Electrical Components

Follow the manufacturer’s wiring diagram carefully. Key connections include:

- 240V power to the air handler and condenser

- Low-voltage (24V) wires from the thermostat to the control board

- Ground wires for safety

Use wire nuts or push-in connectors for secure joints. Label each wire with tape (e.g., “Y” for cooling, “G” for fan).

Pro tip: Install a surge protector on the condenser’s power line to protect against lightning or power spikes.

Install the Condensate Drain Line

As the AC cools, it removes humidity, which drips as water. This must drain safely.

- Attach a PVC or flexible drain line to the air handler’s drain pan.

- Route it to a floor drain, utility sink, or outside (with a P-trap to prevent odors).

- Use a condensate pump if the line can’t slope downward.

Test the drain by pouring water into the pan—it should flow freely.

5. Connect, Charge, and Test the System

You’re almost there! This final phase brings everything together and ensures your system runs safely and efficiently.

Connect the Indoor and Outdoor Units

With refrigerant lines and wiring in place, it’s time to connect them to the units.

- Attach the lines to the air handler and condenser using torque wrenches (over-tightening can damage valves).

- Connect electrical wires to the terminals (match colors and labels).

- Secure all connections and double-check for leaks or loose parts.

Evacuate the Refrigerant Lines

Before adding refrigerant, you must remove air and moisture from the lines. This is done with a vacuum pump.

- Connect the manifold gauge set to the service ports.

- Open the valves and run the vacuum pump for at least 30–60 minutes.

- Use a micron gauge to ensure pressure drops below 500 microns.

Note: This step is critical. Moisture in the system can freeze and damage the compressor.

Charge the System with Refrigerant

Only EPA-certified technicians should do this. They’ll:

- Weigh in the correct amount of refrigerant (listed on the unit’s label).

- Monitor pressures and temperatures to fine-tune the charge.

- Ensure the subcooling and superheat levels are within specs.

An over- or under-charged system wastes energy and shortens lifespan.

Test the System

Once charged, turn on the system and run it through a full cycle. Check:

- Airflow from vents (should be strong and even)

- Temperature drop across the coil (should be 15–20°F)

- No unusual noises (buzzing, rattling, or hissing)

- Thermostat communication (should turn on/off correctly)

Run it for 30+ minutes to ensure stable operation. If anything seems off, shut it down and call a pro.

6. Final Touches and Maintenance Tips

Congratulations—your central air conditioner is installed! But the work doesn’t stop here. Proper maintenance keeps it running smoothly for years.

Insulate and Cover Refrigerant Lines

Wrap the outdoor portion of the refrigerant lines with UV-resistant line cover. This protects them from sun, rain, and physical damage.

Program Your Thermostat

Use a programmable or smart thermostat to save energy. Set it to:

- 78°F when you’re home

- 82–85°F when you’re away

- Adjust based on your schedule and comfort

Smart thermostats (like Nest or Ecobee) can learn your habits and optimize cooling.

Schedule Annual Maintenance

Just like your car, your AC needs regular tune-ups. A pro should:

- Clean the condenser coils

- Check refrigerant levels

- Inspect electrical connections

- Lubricate fan motors

- Test the thermostat and safety controls

DIY tasks you can do:

- Replace air filters every 1–3 months

- Clear debris from around the outdoor unit

- Check the condensate drain for clogs

| Task | Frequency | Cost (DIY) | Cost (Pro) |

|---|---|---|---|

| Air filter replacement | 1–3 months | $10–$20 | $50–$100 |

| Coil cleaning | Annually | $20–$50 | $150–$300 |

| Refrigerant check | Annually | $0 (pro only) | $100–$200 |

| Full system tune-up | Annually | $0 (pro only) | $200–$400 |

Installing a central air conditioner is a big project, but it’s one of the best investments you can make in your home comfort. Whether you DIY with help or hire a pro, understanding the process empowers you to make smart choices. Remember: planning, permits, and proper sizing are just as important as the physical installation.

And once it’s running, don’t forget to enjoy the cool air—maybe with a cold drink in hand. You’ve earned it.

Frequently Asked Questions

How do I install a central air conditioner in my home?

To install a central air conditioner, you’ll need to connect the indoor air handler or furnace, outdoor condenser, refrigerant lines, and thermostat while ensuring proper electrical and ductwork compatibility. It’s recommended to hire a licensed HVAC technician for safe and code-compliant installation, especially for refrigerant handling and electrical connections.

What size central air conditioner do I need for my house?

The correct size depends on your home’s square footage, insulation, climate, and ductwork. A professional load calculation (like Manual J) ensures you select the right BTU capacity—typically 20 BTUs per square foot—to avoid inefficiency or short cycling.

Can I install a central air conditioner myself, or do I need a pro?

While DIYers can handle basic steps like mounting the thermostat or connecting ductwork, central air conditioner installation requires EPA certification for refrigerant handling, electrical work, and system testing. For safety, warranty compliance, and peak performance, professional installation is strongly advised.

How long does it take to install a central air conditioner?

A standard central air conditioner installation typically takes 1 to 3 days, depending on system complexity, ductwork modifications, and whether the furnace or air handler needs upgrades. New construction installations are often faster than retrofitting older homes.

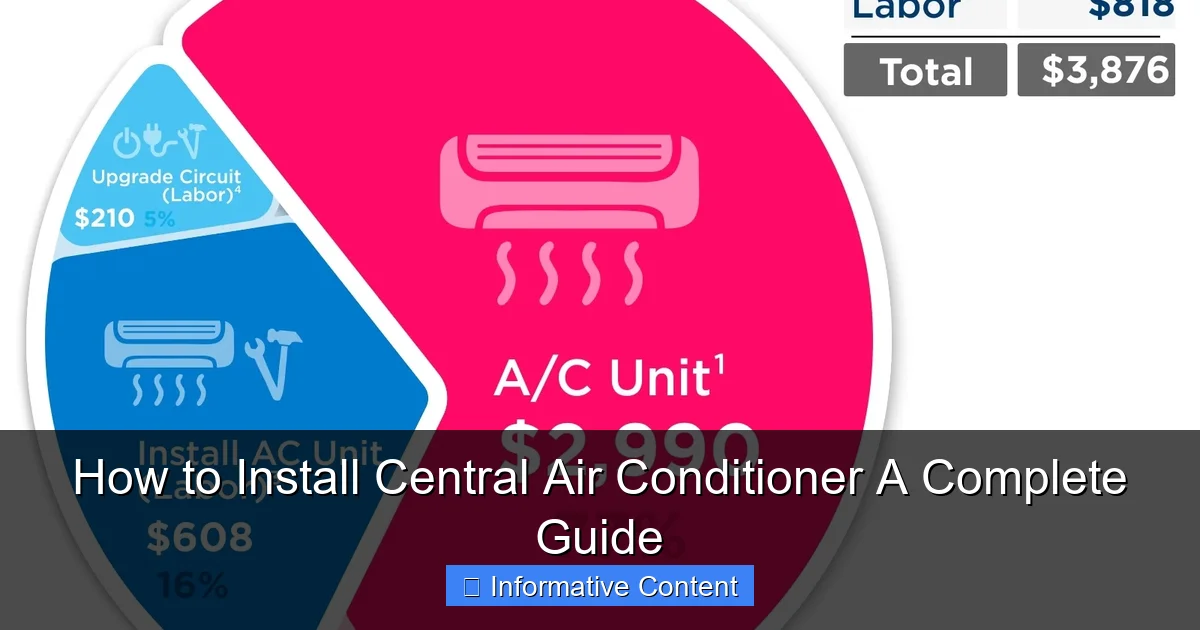

What are the costs involved in installing a central air conditioner?

Installation costs range from $3,000 to $7,000+ depending on unit size, SEER rating, labor, and ductwork needs. High-efficiency models and complex retrofits increase the price, but rebates and tax credits may help offset expenses.

Do I need to replace my furnace or ducts when installing central air?

If your furnace or air handler is compatible and in good condition, you may only need to add an evaporator coil. However, outdated or undersized ductwork often requires upgrades to ensure efficient airflow for your new central air conditioner.