When brazing HVAC pipes, choose high-temperature brazing rods for stronger connections. Using tin/silver alloy can lead to weaker joints than higher-temperature brazing rods.

The choice of material for HVAC pipe brazing is crucial for the longevity and reliability of the connections. For efficient and durable HVAC pipe installation, selecting the right brazing rod is essential. Higher temperature brazing rods are recommended for their superior strength and reliability compared to tin/silver alloy.

The failure of connections adjacent to the braze is significantly lower with higher-temperature brazing rods, ensuring secure and long-lasting joints in HVAC systems. By understanding the best materials for HVAC pipe brazing, technicians can ensure optimal performance and longevity in their installations. Selecting the appropriate brazing rod is a crucial decision that directly impacts the efficiency and reliability of HVAC systems.

Credit: www.dodomachine.com

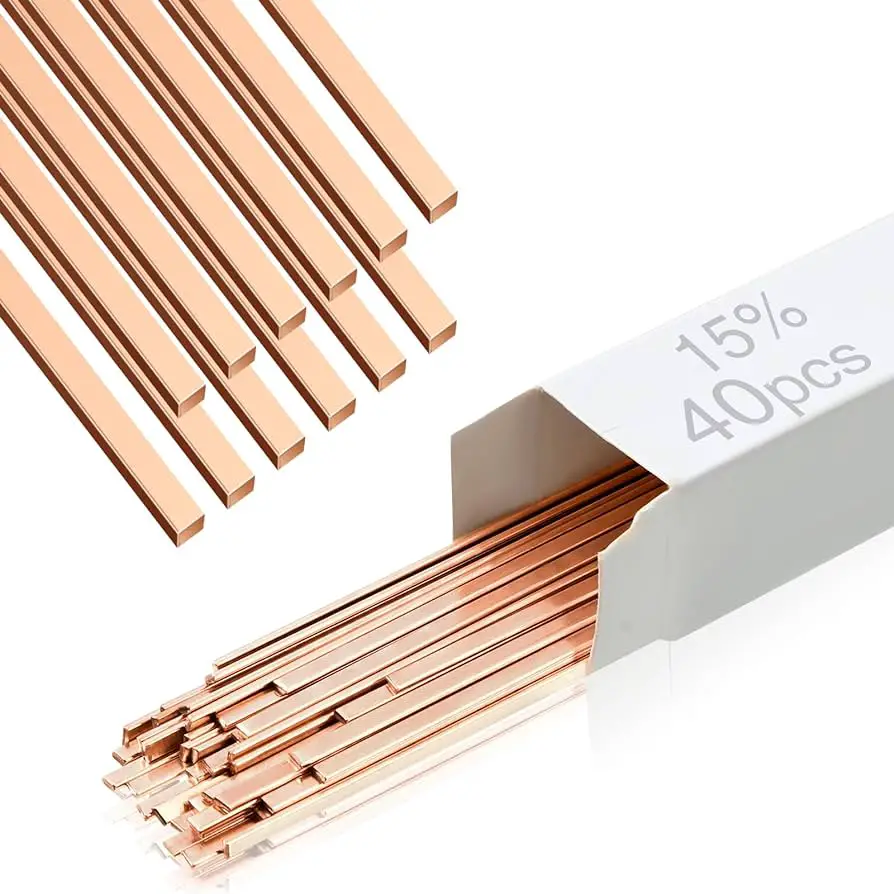

Types Of Brazing Rods For Hvac

Brazing rods play a crucial role in HVAC systems, ensuring strong and reliable connections. Let’s explore the different types of brazing rods commonly used in HVAC applications.

Sil-phos Brazing Rod

Sil-Phos brazing rods are popular for joining copper and brass components in HVAC systems. They contain phosphorus which acts as a flux, facilitating the bonding process.

Aluminum Welding And Brazing Rod

Aluminum welding and brazing rods are used for joining aluminum parts in HVAC systems. These rods are designed to create durable connections in aluminum components.

Bronze Brazing Rod

Bronze brazing rods are ideal for applications where high strength and corrosion resistance are required. They are commonly used in HVAC systems for joining various metal components.

Nickel/silver Brazing Rod

Nickel/silver brazing rods are known for their versatility and ability to join a wide range of metals, making them suitable for different HVAC applications. These rods provide strong and long-lasting connections.

Credit: www.dodomachine.com

Best Practices For Brazing Hvac Pipes

In HVAC pipe brazing, selecting the appropriate brazing rod is crucial for strong joints.

Consider materials like Forney Super Sil Flo Brazing Rod for reliable bonding.

Ensure compatibility with the metals being joined for a durable connection.

Flux plays a key role in the brazing process by facilitating the flow of solder.

- Apply flux evenly on the joint surfaces to aid in uniform brazing.

- Choose flux suited for the specific metals to prevent corrosion issues.

Solder selection is critical; opt for quality options like Bernzomatic Bronze Brazing Rod.

- Ensure the solder alloy matches the base metals for a strong and secure bond.

- Verify the melting point of the solder to align with the brazing temperature.

Common Mistakes In Hvac Pipe Brazing

When it comes to HVAC pipe brazing, it’s important to be aware of the common mistakes that can compromise the integrity of the connections. Understanding these mistakes and knowing how to avoid them is crucial for ensuring the reliability and longevity of HVAC systems. Below, we’ll discuss the most common pitfalls associated with HVAC pipe brazing, including the failure of higher temperature brazed connections, the difference between soldering and brazing in HVAC, and the proper usage of flux.

Failure Of Higher Temperature Brazed Connections

One of the most common mistakes in HVAC pipe brazing is the failure of higher temperature brazed connections. When brazing at higher temperatures, there is a risk of overheating the metals, which can lead to weakened joints and potential leaks. It’s important to ensure that the brazing process is carried out with precision and control to avoid overheating and subsequent failure of the connections.

Soldering Vs. Brazing In Hvac

Understanding the distinction between soldering and brazing in HVAC applications is essential for avoiding mistakes. Soldering is suitable for low-temperature applications and involves melting a filler material into the joint, while brazing is used for higher-temperature applications and requires the filler material to melt and flow into the joint. Choosing the appropriate method for the specific requirements of the HVAC system is crucial to avoid improper bonding and potential failures.

Flux Usage In Hvac Pipe Brazing

Proper flux usage is critical in HVAC pipe brazing to ensure successful and durable joints. Flux is applied to the surfaces being joined to prevent oxidation and facilitate the flow of the brazing filler material. However, using too much or too little flux can lead to subpar brazing results. It’s important to apply the appropriate amount of flux and ensure that it is evenly distributed to promote effective brazing.

Credit: www.amazon.com

Frequently Asked Questions On Hvac Brazing Rod

What Type Of Brazing Rods For Hvac?

The best type of brazing rod for HVAC is one that contains tin/silver alloy. These rods provide strong and reliable connections for HVAC pipes, with a lower failure rate compared to higher temperature brazed connections. Tin/silver alloy is a preferred option for HVAC pipe brazing, ensuring durability and efficiency in the system.

Which Is The Best Material To Use On Hvac Pipe Brazing?

The best material to use on HVAC pipe brazing is a tin/silver alloy. It provides stronger connections that are less likely to fail under high pressure compared to other materials.

Do You Use Flux When Brazing Hvac Lines?

Yes, flux is used when brazing HVAC lines for a clean and strong joint.

What Solder For Hvac Lines?

For HVAC lines, the best solder to use is a tin/silver alloy. It provides stronger connections compared to higher temperature brazing rods.

Conclusion

Choosing the right brazing rod for HVAC applications is crucial for the longevity and effectiveness of the connections. While there are various options available in the market, it’s important to consider the type of metal being used and the working temperature to determine the most suitable brazing rod.

Additionally, understanding the difference between soldering and brazing can help in making informed decisions for HVAC projects.