Have you ever experienced your AC system blowing out warm air instead of cool, and wondered what may be causing it? The culprit could be a faulty compressor. Checking your compressor should be part of your regular maintenance routine to avoid such issues. It doesn’t necessarily require professional assistance as you can easily check the compressor yourself.

In this blog, we’ll take you through the basics of checking your compressor and identifying the warning signs that indicate it needs to be repaired or replaced. So, let’s dive in!

Visual Inspection

If you’re wondering if your compressor is working properly, a visual inspection can give you a good idea. Start by checking the electrical connections for any signs of wear or damage. Look for frayed wires or loose connections.

Next, give the compressor housing a once-over for any cracks or leaks. These could indicate a much larger problem, so it’s important to address them right away. Look at the pressure gauge on the compressor to see if it’s within the recommended range.

If it’s outside of the range, it’s likely that the compressor isn’t working correctly. Finally, listen closely to the compressor as it runs. If it’s making unusual sounds or seems to be working harder than usual, it could be a sign that something is wrong.

By performing these simple checks, you can get a better idea of whether or not your compressor is working properly.

Check for Physical Damage

When it comes to inspecting your device for potential physical damage, a thorough visual inspection should be your first step. This involves examining the exterior of the device for any cracks, dents, or scratches. It’s important to pay close attention to any areas that are prone to damage, such as the screen, corners, and edges.

You should also check for any signs of water damage, such as corrosion or rust. If you notice any physical damage, it’s important to address it right away in order to prevent further problems down the line. By taking the time to carefully inspect your device, you can potentially avoid costly repairs or replacements in the future.

So, don’t hesitate to give your device a good once-over and ensure that it’s in top condition.

Check for Oil Leaks

When it comes to car maintenance, one crucial aspect that you shouldn’t overlook is checking for oil leaks. Oil leaks can cause serious damage to your engine and compromise your car’s overall performance. The good news is, it’s relatively easy to check for oil leaks.

One quick and easy way is to visually inspect your car’s engine and look for any signs of oil leaking. If you notice any wet spots or puddles of oil under your car, that’s a definite sign that there’s a leak. You should also check the engine oil levels regularly to ensure that your car has enough oil.

Low oil levels can cause your engine to overheat, which can lead to more serious problems. By keeping an eye out for any signs of oil leaks, you can catch the problem before it causes any significant damage to your car. So, the next time you’re checking your car’s maintenance needs, remember to check for oil leaks.

Your engine will thank you for it!

Testing the Compressor

The compressor is an essential part of an air conditioning system. When it’s not working, your AC won’t be able to cool your space effectively. If you’re experiencing issues with your AC, one of the first things you need to check is the compressor.

The good news is that there are a few ways to test the compressor to see if it’s functioning correctly. One of the best ways is to use a multimeter to check the electrical readings of the compressor. If the readings are within the manufacturer’s specifications, it’s likely that the compressor is working fine.

Another way to test the compressor is to observe the condenser unit. If the fan is running, but the compressor isn’t, you may have a problem with the compressor. Additionally, if you notice strange noises coming from the condenser unit, it’s a sign that something is wrong with the compressor.

By regularly testing the compressor, you can catch any issues early on and avoid costly repairs down the road.

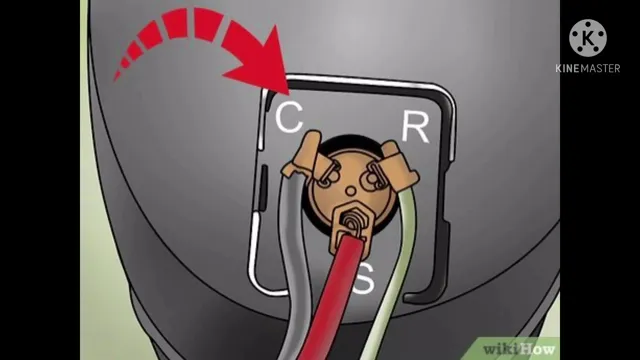

Check Resistance with a Multimeter

If your refrigerator or air conditioner compressor is not working, one reason could be a damaged winding in the compressor motor. To test this, you can use a multimeter to check the compressor’s resistance. First, disconnect the power supply from the appliance and locate the compressor.

Then, set your multimeter to the resistance measuring mode and touch the probes of the meter to the two pins on the compressor motor. A good winding will have a resistance value within the manufacturer’s specifications, while a damaged winding will show a higher or lower resistance value. By testing the compressor with a multimeter, you can quickly identify if there’s an issue with the compressor motor before proceeding with repairs.

This simple test can save you time and money in the long run and help your appliance to function efficiently.

Check Voltage Across the Compressor

When it comes to testing the compressor of your HVAC system, one important step is to check the voltage across it. This involves using a multimeter to measure the voltage at the terminals of the compressor while it is running. The reading should be within the manufacturer’s specifications, which can be found in the manual or online.

If the voltage is too high or too low, it could indicate a problem with the electrical circuit or the compressor itself. Checking the voltage across the compressor is crucial, as it helps to ensure that it is operating properly and efficiently. Think of it like checking the blood pressure of a patient – it gives you an idea of how well their heart is functioning.

In the same way, checking the voltage across the compressor gives you insight into the overall health of your HVAC system. Whether you’re a homeowner or HVAC technician, be sure to include this step in your compressor testing routine.

Listen and Feel for Vibrations

When it comes to HVAC systems, the compressor is like the heart of the unit. It’s what pumps refrigerant throughout the system to provide cooling. So, if something goes wrong with the compressor, it could lead to major issues for the entire system.

That’s why it’s important to test the compressor regularly. One way to do this is to listen and feel for vibrations. When the compressor is running, it should be relatively quiet and smooth.

If you hear unusual noises or feel excessive vibrations, that could indicate a problem with the compressor. It’s important to address any issues with the compressor as soon as possible to prevent further damage and ensure your HVAC system is running smoothly. So, if you haven’t checked on your compressor recently, it’s a good idea to schedule a professional inspection.

Conclusion

In conclusion, checking if the compressor is working is a crucial step in ensuring the proper functioning of your AC unit. From listening for the hum of the compressor to feeling the cool air coming from the vents, the signs are there if you know where to look. So don’t let a faulty compressor put a damper on your summer cool-down plans.

Give your unit a quick check and keep the cool air flowing with ease. Remember, a working compressor means a happy home and a happy wallet, so keep calm and compressor on!”

Summary of Steps Taken

To test the compressor, several steps were taken to ensure it was in good working order. First, the power supply was checked to ensure the compressor had the necessary power to operate. Next, the air filter was inspected and cleaned to ensure proper airflow.

Then, the pressure switch was tested to ensure it was functioning correctly and the pressure gauge was checked for accuracy. After that, the safety valve was tested to ensure it would release excess pressure if needed. Finally, the compressor was run for an extended period to ensure it could maintain pressure and didn’t overheat.

By following these steps, it was determined that the compressor was in good working order and ready for use. In conclusion, testing the compressor is an important step to ensure it functions correctly and is safe to use. By following a set of specific steps and checks, it can be determined if the compressor is ready for use or if any repairs need to be made.

This ensures both safety and efficiency, making it an essential part of maintenance for any air compressor.

When to Seek Professional Help

When it comes to testing the compressor, it’s important to know when to seek professional help. If you notice that your compressor is making unusual noises or struggling to start up, it may be time to bring in an expert. A professional can ensure that your compressor is working at its optimal level and diagnose any potential issues before they turn into major problems.

It can be tempting to try to handle the issue on your own, but without the proper knowledge and tools, you may end up causing more damage. Don’t hesitate to reach out to a professional if you suspect that your compressor needs attention. They can help you keep your compressor running smoothly and avoid any costly repairs in the future.

FAQs

How can I check if my compressor is working properly?

You can check if your compressor is working by listening for unusual sounds, checking for proper airflow, and monitoring the temperature of the air coming out of the system.

What are the signs that my compressor is failing?

Some signs that your compressor is failing include unusual sounds coming from the system, poor airflow or inadequate cooling, and inconsistent temperatures.

Can a failing compressor cause other HVAC system issues?

Yes, a failing compressor can cause other HVAC system issues, such as reduced cooling capacity, increased energy usage, and even complete system failure.

How often should I have my compressor checked for maintenance?

It is recommended that you have your compressor checked for maintenance at least once a year, preferably before the start of the cooling season. Regular maintenance can help extend the life of your compressor and prevent costly repairs.