Compressors are widely used in various industries for a wide range of applications – from air conditioning units in homes to powering large-scale manufacturing processes. But did you know that counting the stages in your compressor is crucial to understanding its efficiency and performance? In simple terms, a compressor stage refers to the number of times the air is compressed before being released. This means that the more stages a compressor has, the higher the pressure of the air it can deliver.

But at the same time, having too many stages can lead to reduced efficiency and increased energy consumption. Understanding the number of stages in your compressor can help you determine if it is suitable for your current needs and identify any potential maintenance or efficiency issues. It can also help you make informed decisions when it comes to choosing the right compressor for your industry or application.

So the next time you come across a compressor, take a closer look at its stages and see how it impacts its performance. Whether you are a seasoned professional or just starting to learn about compressors, understanding the importance of counting your compressor stages is something you cannot ignore.

Understanding the Basics

If you’re wondering how many compressor stages your equipment has, it’s crucial that you understand the basics of compressor technology. Typically, compressor stages refer to the number of times air is compressed before it gets to its final output. For instance, a single-stage compressor compresses air once, while a two-stage compressor compresses it twice.

In general, the higher the number of compressor stages, the more efficient the compressor will be. This is because the air pressure will be built up progressively, resulting in less work for the final stage. However, it is essential to note that different types of compressors can have varying numbers of stages.

Consult your equipment manual to determine the number of compressor stages your compressor has, or speak to a qualified technician for more information.

What are Compressor Stages?

Compressor stages are critical components of air compression systems. A compressor stage refers to a singular section within a compressor where air is compressed. A typical compressor consists of multiple stages linked together to produce high-pressure air for different applications.

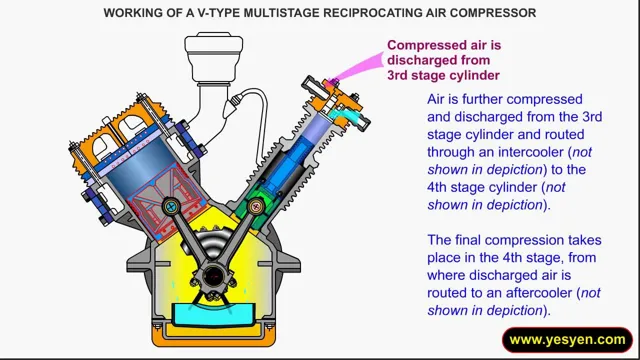

The quantity of stages in a compressor determines its compression ratio, which is the relation between the air’s outgoing and incoming pressures. Single-stage compressors are commonly used for low-pressure applications such as home garages and small shops. Multi-stage compressors, however, are utilized for high-pressure applications such as commercial and industrial settings.

Multi-stage compressors use multiple stages of decreasing size to produce higher compression ratios to meet the high-pressure demands of industrial processes. Whether you need a single-stage or multi-stage compressor, it’s essential to understand compressor stages and select the right one for your specific application.

Why does it Matter?

Understanding the basics of any topic is crucial to gaining a deeper insight into its importance. The same holds for the question of why it matters to learn new things. Learning is the process of acquiring and understanding knowledge, skills, and values, which has a significant impact on our personal and professional growth.

It allows us to grasp concepts and ideas, leading to improved decision-making abilities. Furthermore, it helps us adapt to changes, making us more flexible and open-minded individuals. In today’s fast-paced world, those who embrace the concept of lifelong learning are the ones who stay ahead in their careers, unlock new opportunities, and become more fulfilled in their personal lives.

Therefore, understanding the basics of learning is essential to recognize its significance and enhance our lives positively.

Determining Your Number of Stages

If you’re wondering how many compressor stages your system has, there are a few factors to consider. First, you’ll want to check the specifications for your specific compressor model. Typically, the number of stages will be listed there.

If you don’t have access to the specs, you can try counting the number of cylinders on your compressor. Each cylinder typically represents one compressor stage. Additionally, you can look at the pressure ratio of your compressor.

This ratio, which is the ratio of your output pressure to your input pressure, typically increases with each stage. So, if you know the pressure ratio and the maximum pressure output of your compressor, you can work backwards to estimate the number of stages. Keep in mind, however, that the actual number of stages can vary depending on several factors, including the design of your compressor and any modifications that may have been made to it.

Locate Your Compressor Manual

When it comes to understanding your compressor’s functionality and maintenance requirements, your manual is your go-to resource. Before you even begin using your machine, it is crucial to determine the number of stages it operates on. But what exactly does that mean? The number of stages refers to the number of times the air is compressed before it is used.

A single-stage compressor has only one piston that compresses the air, while a two-stage compressor has two. The latter is typically more efficient as it uses less energy to compress the same amount of air, making it ideal for high-demand applications. To determine the number of stages, you can start by taking a look at your compressor’s manual, which provides all the necessary information on its features and specifications.

This will give you an idea of what you’re working with and how to operate your compressor effectively and safely.

Inspect Compressor Construction

When inspecting compressor construction, one of the critical factors to consider is determining your number of stages. The number of stages refers to the number of times the air is compressed before it’s released. Each stage in a compressor features a rotor and a stator.

The stator is stationary, while the rotor rotates and compresses the air. Two-stage compressors are the most common, with the first stage compressing the air to an intermediate pressure before the second stage compresses it further. However, larger applications may require three or more stages for optimum compression.

Multi-stage compressors are more efficient, run cooler and quieter, and are the go-to for industrial applications. By carefully determining your compressor’s number of stages, it is possible to improve its overall efficiency, performance, and lifespan.

Count the Number of Stages

Determining the number of stages for your project can be a daunting task. However, it’s an essential component to ensure that your project is well-organized and progresses smoothly to completion. To determine the number of stages, you need to consider the tasks involved and the resources required to complete them.

A critical aspect to keep in mind is that your stages must be achievable, measurable, and distinct from one another. Every stage must have a specific start and end date, with clear objectives and milestones that act as indicators of progress. It’s crucial to keep your project’s time constraints, budget, and feasibility in mind when deciding on the number of stages.

You don’t want to end up with too many stages that make your project management complicated, nor do you want to have too few stages that compromise your project’s quality. Determine the optimal number of stages, and you’ll have a well-planned project that is easy to manage from start to finish.

Types of Compressors

If you’re wondering how many compressor stages you have, it really depends on the type of compressor you’re using. Compressors can have anywhere from one to multiple stages, each serving a specific purpose in the compression process. In a single-stage compressor, the entire compression process happens in one step, compressing the gas to the desired pressure in one stroke.

On the other hand, multistage compressors use a series of different-sized cylinders to gradually increase the pressure and reduce energy consumption. Usually, compressors with more stages are more efficient and can handle higher pressure ratios, making them suitable for industrial and heavy-duty applications. However, single-stage compressors are more straightforward and cost-effective for smaller tasks.

So, the number of compressor stages you have ultimately depends on your specific needs and usage.

Single Stage vs Multi Stage

When it comes to compressors, there are two main types to choose from: single-stage and multi-stage. Single-stage compressors are simpler and less expensive, but they don’t offer the same level of power or efficiency. Multi-stage compressors, on the other hand, use multiple cylinders to compress air in stages, allowing for greater power and efficiency.

Just like a bicycle with multiple gears, a multi-stage compressor can adjust its power output to match your needs. Need a burst of power to get through a tough job? Kick it up to a higher gear. Need to maintain a steady level of pressure? Keep it in a lower gear.

Of course, with greater power and efficiency comes a higher price tag. Multi-stage compressors are typically more expensive than their single-stage counterparts, but they can also save you money in the long run by consuming less energy and lasting longer. Ultimately, the choice between single-stage and multi-stage compressors comes down to your specific needs and budget.

Advantages and Disadvantages

When it comes to compressors, there are a few different types to choose from. One common type is the reciprocating compressor. These compressors use a piston to compress the gas and are often found in small-scale applications.

They are relatively easy to maintain, and their simple design makes troubleshooting any issues a breeze. However, reciprocating compressors can be quite noisy and have a limited lifespan compared to other types. Another popular option is the rotary screw compressor.

These compressors use two interlocking screws to compress the gas and are more efficient than reciprocating compressors. They are also quiet, making them a good choice for indoor use. However, rotary screw compressors can be expensive, and their complex design can make troubleshooting more difficult.

Ultimately, the type of compressor you choose will depend on your specific needs and budget.

Maximizing Compressor Performance

If you’re wondering how many compressor stages you have, the answer depends on several factors. Compressors are designed with multiple stages to provide higher overall performance and efficiency. The number of stages in a compressor depends on the application and the desired output.

Generally, the number of stages increases as the required pressure ratio increases. In some cases, a single-stage compressor is enough to provide the required pressure, while in others, a multistage compressor is necessary. The more stages a compressor has, the higher its efficiency, but also the more expensive it becomes.

Therefore, it is important to consider the specific needs of your application before deciding on the number of compressor stages. Ultimately, choosing the right number of stages is key to maximizing compressor performance and minimizing energy costs while maintaining the desired pressure output.

Conclusion

Well, my dear friend, asking how many compressor stages you have is like asking how many layers are in a croissant – it all depends on the recipe and the desired outcome. Whether you have two, three, or four stages, what truly matters is finding the perfect balance between efficiency and output for your specific needs. So, don’t get too caught up in the number game and focus on creating the perfect blend of air compression for your next project.

Happy compressing!”

FAQs

What is the purpose of compressor stages in a gas turbine engine?

The compressor stages compress the incoming air to allow for more efficient combustion in the engine.

How many compressor stages are typically found in a gas turbine engine used for aviation?

Gas turbine engines used for aviation can have anywhere from 1 to 17 compressor stages, depending on the specific design of the engine.

How does the number of compressor stages affect the performance of a gas turbine engine?

The number of compressor stages can impact the engine’s efficiency and power output. Engines with more compressor stages generally have better performance but can also be more complex and expensive.

Is it possible to add or remove compressor stages from a gas turbine engine?

While it is technically possible to modify the number of compressor stages in a gas turbine engine, it is generally not recommended as it can significantly alter the engine’s performance and could potentially cause safety issues. Any modifications should be made by a qualified professional with expertise in the specific engine and design.