When the summer heat hits, an air conditioner becomes your best friend. However, when your AC filter starts to bend, you may find yourself in a pickle. A bent filter can cause all sorts of problems, from poor air quality to a decrease in the efficiency of your AC.

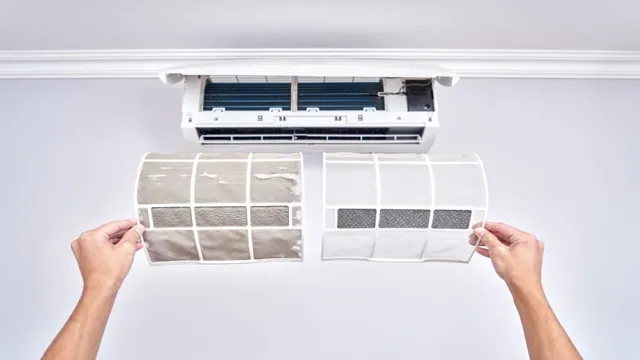

But fret not. You can easily fix this issue with a few solutions. First off, you need to check if the bent filter is clogged with dust and debris.

If so, it’s time to give it a good cleaning. Use a soft brush to remove any visible dirt, or if it’s too clogged, try using a vacuum to suck out the dirt. Sometimes, a thorough cleaning alone can fix the problem.

If that doesn’t work, it’s time to replace the filter. Filters are cheap and easily accessible. All you need to do is buy the right size and type of filter, remove the old one, and replace it with the new one.

This solution is quick, easy, and ensures that your AC is operating at peak efficiency. However, if you find that the filter keeps bending no matter what you do, it’s best to call in a professional. A qualified technician can inspect your unit to identify the root cause of the problem and provide a lasting solution.

a bent AC filter is a common issue that can be easily resolved with a bit of effort. Whether it’s a simple cleaning or replacement, there are solutions available to ensure that your AC unit remains in top condition. So go ahead, beat the heat, and enjoy the cool breeze!

1. Common Causes of Filter Bending

Firstly, it’s possible that the filter does not fit properly within the frame, leading to excessive pressure in one area. Another reason could be that the filter is made of poor-quality material that cannot withstand the forces of the air passing through it, causing it to deform and bend.

Additionally, excess airflow due to weak airflow restrictions might cause the filter to bend and warp under the pressure. So, before you panic and buy a new filter, take a good look at your AC system, checking for any malfunctions or issues that may lend itself to this problem.

To understand if your filter is too restrictive for the HVAC system, consider the following:

- Equipment Size and Return Dimensions: If the return is too small, it can cause excessive velocity within the ductwork, leading to inefficiencies.

- Filter Type: Stick to cheap fiberglass throwaway filters if you suspect restrictiveness. These are less likely to impede airflow significantly. If you prefer better filtration, consider upgrading to a 4″ or 5″ media filter which balances airflow and efficiency better than standard filters.

- System Performance: A restrictive filter can impede proper airflow, affecting the overall performance of your HVAC system. Monitor for any unusual signs, such as the system working harder than usual.

By evaluating these factors, you can ensure that your filter choice aligns with your system’s requirements, preventing unnecessary strain and maintaining optimal performance.

However, another critical factor to consider is the filter’s restrictiveness. If the filter is too restrictive, it can increase the air velocity within the ductwork, especially if the return air path is undersized for your system’s demands. This could lead to a collapse as the air pressure overwhelms the filter’s structure.

To address these issues, you might want to consider sticking to inexpensive fiberglass throwaway filters unless your system can accommodate a thicker, more durable 4″ or 5″ media filter. These options can help balance airflow and reduce the risk of deformation.

So, before you panic and buy a new filter, take a good look at your AC system, checking for any malfunctions or issues that may lend themselves to this problem. Understanding the root cause, whether it’s a poor fit, material quality, or system mismatch, is key to finding a lasting solution.

However, it’s also crucial to consider whether the filter itself is too restrictive for your HVAC system. A filter that’s too tight can cause excessive velocity within the ductwork, especially if the return is too small relative to the equipment size. This issue often arises when the filter doesn’t match the system’s specifications.

To address this, consider these steps:

- Evaluate Your Filter Type: Stick to cheap fiberglass throwaway filters if you’re unsure about your current setup. They’re less restrictive and easier to manage.

- Upgrade When Necessary: If you want better filtration without compromising airflow, upgrading to a 4″ or 5″ media filter can provide a balanced solution.

By combining these checks and adjustments, you can ensure your HVAC system runs efficiently without unnecessary strain on your filter or ductwork. If the problem persists, try sourcing filters that are stronger and can withstand strong airflow conditions.

Therefore, with close attention to detail, you can ensure that your AC runs smoothly, with a clean and unbent filter that functions correctly.

How to Determine if Your Ductwork is Undersized for Your HVAC System

Ensuring your HVAC system operates efficiently involves assessing if your ductwork is appropriately sized. Undersized ducts can lead to numerous problems, including increased noise and reduced airflow. Here’s a guide to help you determine if your ductwork might be undersized:

Symptoms of Undersized Ductwork

- High Air Velocity: If the air seems to be rushing excessively through the ducts, it could indicate the ductwork isn’t large enough to handle the volume effectively.

- Filter Issues: Using a standard fiberglass filter, observe if it bends or collapses under the pressure. This might mean the ductwork cannot accommodate the air speed, leading to further complications.

- Blower Motor Stress: A variable speed ECM blower is designed to handle a maximum static pressure of around 0.8″ WC. If the pressure exceeds this, it indicates the ducts are struggling, causing the motor to overwork and potentially shortening its lifespan.

- Inadequate Airflow: If rooms in your home are not receiving adequate airflow, it could be a sign that your current ductwork cannot transport enough air due to its size.

Steps to Diagnose and Address the Issue

- Measure Static Pressure: Use a manometer to measure the static pressure in your ducts. Readings higher than recommended levels suggest the ductwork might be too small.

- Check Return Vents: Consider the number of return vents leading to the furnace. Insufficient return venting can strain the system. Adding more return ducts can help relieve pressure and improve airflow.

- Evaluate Filter Restrictions: Pay attention to any filter-related issues. Filters that bow or collapse frequently may indicate undersized ductwork.

Once these indicators have been assessed, consider consulting with an HVAC professional to evaluate and possibly redesign your ductwork. Properly designed duct systems ensure lasting efficiency and performance of your HVAC system.

Understanding Ductwork Size and Filter Performance

The size of your ductwork plays a crucial role in how well your HVAC filters perform. If the ductwork is too narrow, it can create several issues that affect the overall efficiency and performance of your system.

Restrictive Filters and Airflow

- Narrow Ducts: When the ducts are undersized, they may not accommodate the necessary airflow properly. This can result in high air velocity within the duct system, which can be problematic.

- Filter Choice: Opting for highly restrictive filters in such scenarios can further exacerbate the issue. A high-rated filter may clean the air effectively but restrict airflow if the ductwork can’t handle it. This can lead to decreased efficiency and system strain.

Choosing the Right Filter

- Basic Options: For duct systems that are already tight, using simple fiberglass throwaway filters might be the best choice. These filters provide basic filtration while allowing adequate airflow.

- Upgraded Filters: If upgrades are possible, consider a thicker option like a 4” or 5” media filter, offering better filtration without hindering airflow.

Solutions for Improved Airflow

- Multiple Returns: To improve performance, consider adding more return ducts. This setup increases the available surface area for air to flow through, supporting higher cubic feet per minute (CFM) and reducing the velocity within the system.

- Adjusting Fan Speed: If adding extra returns isn’t feasible, another approach is to ensure that the fan isn’t running at an excessively high speed, which can cause undue pressure on existing ductwork.

By understanding the relationship between duct size and filter performance, you can make informed decisions to keep your HVAC system running smoothly and efficiently.

2. Lack of Support at Air Intake

One of the most common causes of filter bending is the lack of support at the air intake. Filters rely heavily on proper support to maintain proper filtration and avoid bending. Without proper support, the filter is more likely to bend, which can lead to decreased performance and premature wear.

This issue is especially prevalent in high-performance vehicles that operate under extreme conditions, as the filter is subject to more stress and is more likely to bend due to the increased airflow. To prevent this, it’s important to ensure that your air intake system is properly installed and supported. This will help to maintain proper airflow and prevent your filter from bending and causing performance issues.

Remember to regularly check your filters and intake system for proper support and function to keep your vehicle running at its best.

Dirty Filters Putting on Additional Pressure

Dirty filters are not only a nuisance, but they can also put additional pressure on your filter system, causing it to bend or break. One of the most common causes of filter bending is dirty filters, which can result in an increase in pressure that the filter is unable to handle. When the pressure on the filter becomes too great, it can cause the filter frame to bend or break, leading to expensive repairs or replacements.

To avoid this issue, it’s essential to clean your filters regularly, ensuring that they are free from any debris or dirt that may cause the increase in pressure. Regular cleaning will not only prolong the life of your filter system but also ensure that it operates efficiently, saving you money in the long run.

Improper Installation and Placement

Improper installation and placement of air filters can cause several issues, including filter bending, which is a common problem. Filter bending occurs when the filter is not installed correctly, and it is not parallel or perpendicular to the airflow. This can lead to gaps in the filter’s sealing edge, which allows the air to bypass the filter, making it inefficient.

Filter bending can also occur if the filter is not supported properly, causing it to sag in the middle and blocking the airflow. Additionally, the location of the filter can cause bending, especially if placed in an area with high airflow. Thus, it is important to make sure the filter is installed correctly, supported, and placed in an appropriate location, avoiding contact with any incoming air, ensuring it functions at its optimal performance.

Failure to do so can reduce the lifespan of the filter and lead to increased energy costs.

Understanding the Impact of Undersized Ductwork on HVAC Filter Performance

Undersized ductwork can significantly hinder the performance of your HVAC system’s filters. Here’s how:

1. Increased Air Velocity

When ductwork is too small, the return air paths are restricted. This results in excessive air velocity through the ducts, which can decrease the efficiency of your filters. With high velocity, there’s more pressure placed on the filter, meaning it has to work harder to allow air to pass through. This not only reduces the filter’s lifespan but also risks damaging the filter structure itself.

2. Filter Overpressure

A good rule of thumb is to keep the pressure drop across the filter below 0.7-0.8 inches of water column. Exceeding this range strains the HVAC motor, potentially shortening its life. Undersized ductwork exacerbates this issue by forcing the system to operate under higher pressure conditions, adding stress to all components involved.

3. Restriction of Airflow

High-efficiency filters, rated 7 or 9 MERV (Minimum Efficiency Reporting Value), can become overly restrictive in a system with undersized ducts. This restriction can cut down the necessary airflow needed for optimal furnace function, resulting in inadequate movement and distribution of conditioned air.

4. Mechanical Stress on Filters

Without adequate surface area in ductwork, excessive air velocity can cause filters to bend or bow. When filters deform, not only is their effectiveness compromised, but they might also allow unfiltered air to bypass them, reducing indoor air quality.

Solutions for Improved Performance

- Increase Filter Surface Area: Consider using filters with a greater surface area. This helps support additional cubic feet per minute (CFM) of airflow and reduces the velocity within ducts, enhancing filter lifespan and efficiency.

- Dual Return Ducts: Implementing two filtered returns instead of one can also alleviate the pressure and ensure adequate airflow, preventing strain on any single filter or return path.

Understanding these dynamics can help you adjust your HVAC setup for better performance and longevity. If adjustments or modifications are beyond your expertise, consulting with a professional can provide a tailored solution to improve both filter performance and overall system efficiency.

Understanding the Impact of Filtered Returns on Air Flow and Filter Performance in HVAC Systems

The number of filtered returns in an HVAC system plays a crucial role in determining both air flow and the overall performance of the system’s filters. Here’s how:

Enhanced Air Flow

- Increased Surface Area: By having multiple filtered returns, the surface area available for air to pass through is significantly increased. This larger area allows the system to support a higher cubic feet per minute (CFM) of air, which refers to the volume of air being moved by the system within a minute.

- Reduced Velocity: With more returns, air moves more slowly through each duct, as the workload is distributed. This reduction in velocity minimizes strain on the system, enhancing its efficiency and lifespan.

Improved Filter Performance

- Even Distribution: Having multiple returns ensures that debris and particulates are collected from various points, which helps in maintaining even air quality throughout the space.

- Longer Filter Life: When air is distributed over several returns, each filter manages less air individually. This reduces the frequency of clogs and extends the operational life of the filters, ultimately saving on maintenance costs.

Additional Benefits

- Quieter Operation: When air flows at a lower velocity due to increased returns, the system operates quieter, which can add to the comfort of occupants.

- Better Temperature Balance: More filtered returns can lead to more consistent heating or cooling, as air is evenly distributed throughout the system.

In summary, increasing the number of filtered returns can substantially boost both air flow efficiency and filter performance in an HVAC system, making it a wise consideration for optimizing indoor environments.

Understanding the Impact of High Static Pressure on an HVAC System with a Variable Speed ECM Blower

Static Pressure and Its Effects

When an HVAC system operates under high static pressure, the performance of the variable speed ECM (Electronically Commutated Motor) blower can be significantly affected. Unlike traditional PSC (Permanent Split Capacitor) motors, ECM blowers are designed to handle higher static pressures, typically up to 0.8 inches of water column (“”WC).

Risks of Exceeding Optimal Levels

- Motor Overstrain: Operating above the recommended static pressure range can lead to motor strain. If the static pressure surpasses 0.7–0.8 inches WC, the ECM blower can become overworked, leading to premature wear and tear.

- Efficiency Loss: High static pressure reduces the system’s efficiency. The blower must exert more effort to circulate air, causing increased energy consumption and potentially higher utility bills.

- Longevity Concerns: Consistently operating under excessive pressure diminishes the lifespan of the blower motor. This can result in more frequent repairs or replacements, leading to additional costs and inconveniences.

Maintaining Optimal Performance

To ensure your HVAC system functions effectively and efficiently, regularly monitor static pressure levels and maintain them within the recommended range. Investing in proper ductwork design and routine maintenance can help mitigate high static pressures and extend the life of your ECM blower.

Enhancing HVAC Airflow and Filter Performance with Additional Returns

Adding extra returns to your HVAC system can significantly improve both airflow and filter performance. Here’s how:

- Increased Airflow Capacity: By incorporating more return ducts, you expand the pathway for air to flow back to the furnace or air handler. This additional passage reduces bottlenecks, allowing your system to handle more cubic feet per minute (CFM) efficiently.

- Reduced Air Velocity: With more returns, the velocity of air flowing through the ducts decreases. This reduction means less strain on your system, minimizing noise and improving overall comfort levels as air circulates more evenly.

- Enhanced Filter Efficiency: Significant surface area harnessed from more returns means that filters can capture more particles without becoming clogged too quickly. Filters thus work at optimal performance for longer periods, promoting better indoor air quality.

- Balanced System Pressure: Adding returns helps to balance air pressure within the HVAC system, preventing pressure imbalances that can lead to drafts or uneven heating and cooling throughout your home.

- Prolonged System Life: With improved airflow and less strain on your components, your HVAC system is likely to experience less wear and tear, potentially extending its operational life and reducing maintenance costs.

By optimizing these aspects through additional returns, your HVAC system will perform more efficiently, leading to enhanced comfort and better air quality in your indoor spaces.

Understanding the Different Grades of HVAC Filters and Their Impact on Performance

When it comes to HVAC filters, understanding the variety of grades is crucial for optimizing both air quality and system efficiency. The standard used to measure filter effectiveness is the MERV rating, which stands for Minimum Efficiency Reporting Value. This scale helps determine how well a filter can capture particles of different sizes.

Here’s a rundown of the various MERV grades and their implications:

- MERV 1-4: These are the most basic filters, often the least expensive. They offer minimal filtration, capturing only large particles such as dust and pollen. Ideal for residential buildings where air quality needs are less stringent.

- MERV 5-8: These filters provide better filtration, suitable for homes and basic commercial settings. They can trap smaller particles like mold spores and hair spray, improving indoor air quality significantly without overly restricting airflow.

- MERV 9-12: Suitable for higher quality air needs, these filters can capture finer particles such as lead dust and some bacteria. They are commonly used in hospitals and commercial spaces where air quality is a critical factor.

- MERV 13-16: Offering near-HEPA (High-Efficiency Particulate Air) filtration levels, these filters are excellent for individuals needing superior air quality, such as those with allergies or respiratory issues. They can trap very fine particles, including smoke and some viruses.

Why MERV Ratings Matter

Choosing the right MERV rating is essential not only for air quality but also for system performance. A filter with a high MERV rating is efficient at trapping particles but may also hamper airflow if the system isn’t designed to accommodate it. This can put a strain on your HVAC system, potentially leading to higher energy costs and maintenance issues.

Before making a selection, consider your specific air quality needs and HVAC system capabilities. For instance, using a MERV 7 filter could be a good balance between efficiency and maintaining proper airflow in many household systems.

Understanding MERV in HVAC Filters

When exploring HVAC filters, you’ll frequently encounter the term MERV, which stands for Minimum Efficiency Reporting Value. This standard rating helps you gauge a filter’s effectiveness in capturing airborne particles.

How MERV Ratings Work

- Range: MERV ratings generally range from 1 to 16. Higher numbers indicate a filter’s ability to capture smaller particles more efficiently.

- Low MERV (1-4): These filters, often affordable, trap the largest particles like dust and pollen. A basic household filter typically falls into this category.

- Medium MERV (5-8): Suitable for most residential settings and some commercial ones, these filters can capture smaller particles like mold spores and finer dust.

- High MERV (9-12): Offering enhanced air quality, these filters are effective in capturing larger allergens and some bacteria. They are ideal for individuals with allergies or asthma.

- HEPA-Grade (13-16): At this level, filters approach HEPA standards, capturing tiny particles such as smoke, bacteria, and even viruses. These are often used in hospitals or cleanroom environments.

Making the Right Choice

Selecting the appropriate MERV rating depends on your specific needs, such as indoor air quality requirements and your HVAC system’s capacity to handle different filter densities. The key is balancing filtration efficiency with system compatibility to ensure optimal performance and longevity.

What About Other Rating Systems?

While MERV is the industry standard, some brands like 3M use their own proprietary rating systems to denote filter efficacy. These can sometimes exceed MERV ratings but may not be directly comparable. Always cross-reference these ratings to ensure you are selecting a filter that’s truly effective for your needs.

In summary, understanding and choosing the correct filter grade is key to maintaining good indoor air quality while ensuring your HVAC system runs smoothly and efficiently.

When choosing filters for your HVAC system, it’s crucial to understand the compatibility and efficiency of higher-rated options, such as FPR 7 and 9. While these filters are designed to trap more particles and improve air quality by filtering smaller particles, their use might not be ideal for every system.

Understanding Filter Ratings

- FPR 7 and 9 filters are highly effective at capturing dust, pollen, mold spores, and even bacteria. They are excellent for enhancing indoor air quality.

- Higher Restriction: These filters can restrict airflow significantly more than lower-rated options, which could potentially lead to inefficiencies.

HVAC System Compatibility

- Airflow Requirements: Certain HVAC systems require a specific amount of airflow to operate efficiently. Filters with high ratings like FPR 7 and 9 may impede this airflow if the system isn’t designed to handle the extra restriction.

- Potential Strain: Using more restrictive filters without proper system adjustment can cause the filters to bend or bow, reducing their effectiveness and potentially straining your HVAC components.

Recommendations

- Multiple Returns Needed: To maintain adequate airflow and avoid bending or bowing, you might need two or more filtered returns if opting for higher-rated filters.

- Consult an Expert: Before upgrading your filter, it’s wise to consult with an HVAC professional who can assess whether your system can support these filters without compromising performance.

In summary, while high-efficiency filters can improve air quality, they may not be suitable for all systems without modifications. Ensuring your HVAC system can manage the airflow needed to accommodate these filters is key to avoiding unnecessary upgrades or potential damage.

Understanding Static Pressure and Its Impact on Filter Performance

When discussing HVAC systems, particularly those equipped with a variable speed ECM blower, understanding static pressure is crucial for optimal performance and longevity. Here’s how static pressure affects filter performance:

What is Static Pressure?

Static pressure refers to the resistance to airflow within your HVAC system. It’s typically measured in inches of water column (in. WC). Systems with high static pressure face greater resistance, which can lead to reduced efficiency and increased wear and tear.

Impact on Filter Performance

- Decreased Airflow: When static pressure is high, the blower motor must work harder to move air through the system. This can reduce overall airflow, impacting the amount of air passing through the filter. Inadequate airflow means that your filter might not be able to capture and remove particulates as effectively.

- Motor Strain: Operating beyond the recommended static pressure levels, typically between 0.7 to 0.8 in. WC for a variable speed ECM blower, can strain the motor. This can result in higher energy consumption and potentially shorten the motor’s lifespan.

- Filter Longevity: Filters subjected to high static pressure may have a reduced lifespan. The increased resistance means contaminants accumulate faster, necessitating more frequent replacements to maintain good air quality and system performance.

Optimizing Filter Performance

- Routine Maintenance: Ensure regular maintenance checks to monitor static pressure, replacing filters as needed and cleaning components that might contribute to increased pressure.

- Proper Sizing: Use the correct filter size and type for your HVAC system to prevent unnecessary resistance.

By managing static pressure effectively, you not only extend the life of the blower motor but also enhance the efficiency and effectiveness of your HVAC system’s air filtration.

Understanding Variable Speed ECM Blowers and Static Pressure

A variable speed ECM (Electronically Commutated Motor) blower is a technologically advanced component often found in modern HVAC systems. Unlike traditional PSC (Permanent Split Capacitor) motors, these ECM blowers are designed to handle higher levels of static pressure — up to 0.8 inches of water column (“”WC).

Benefits of ECM Blowers

- Enhanced Efficiency: ECM blowers adjust their speed based on the system’s needs, which results in optimal energy consumption and efficiency.

- Improved Air Quality: By maintaining a consistent airflow, ECM blowers help ensure air is evenly distributed throughout the space, enhancing comfort and air quality.

- Longevity: Operating within recommended static pressure levels, typically not exceeding 0.7 to 0.8″”WC, ensures the blower does not become overworked, thus prolonging its life span.

Why Static Pressure Matters

Static pressure refers to the resistance to airflow within your HVAC system. Managing this pressure is crucial because:

- System Performance: Excessive static pressure can lead to reduced system performance.

- Component Strain: Too much pressure can strain the blower motor, leading to increased wear and tear and potential failures.

By being mindful of these factors, you can enjoy efficient operation and longer-lasting performance from a variable speed ECM blower.

How Increasing Main Returns Benefits Air Flow and Filter Performance

Expanding the number of primary air returns to your furnace can significantly influence both airflow and the effectiveness of your filters. Here’s how:

Enhanced Air Flow

- Improved Circulation: By adding more main returns, air can circulate more efficiently throughout your HVAC system. This enhancement supports increased cubic feet per minute (CFM), allowing your system to handle a larger volume of air with ease.

- Reduced Air Velocity: With greater surface area available through additional returns, the speed of the air moving through the ducts decreases. This reduction in velocity means quieter operation and less wear and tear on the system.

Superior Filter Performance

- Better Filtration Efficiency: When air moves through the system at a lower velocity, filters have more time to capture particles and contaminants. This improved filtration efficiency translates to cleaner air being delivered throughout your home.

- Extended Filter Life: With a decrease in air speed, there is less force exerted on filters, leading to reduced stress and longer lifespan. This can mean less frequent replacements and cost savings over time.

By expanding the number of main returns, you not only bolster your system’s air handling capabilities but also enhance indoor air quality through improved filter performance.

Having multiple return vents in your home plays a crucial role in enhancing the efficiency and performance of your heating and cooling system. Here’s why:

Improved Airflow

Multiple return vents allow for a more balanced airflow throughout the house. By distributing the air intake across several points, your system can circulate air more evenly and efficiently, ensuring that all areas remain comfortable.

Enhanced System Efficiency

With additional return vents, the total surface area for air return increases. This expansion not only supports a higher cubic feet per minute (CFM) of airflow but also reduces the speed of air traveling through the ducts. Lower velocity means less noise and less strain on the ductwork, prolonging the life of your heating and cooling system.

Better Filtration and Air Quality

By having multiple return points, the load on your HVAC filters is spread out. This setup can lead to better filtration as the air travels more gradually through the system, allowing the filters to catch more dust and allergens. It can result in cleaner indoor air and a healthier living environment.

Optimized System Performance

A well-distributed return vent system can prevent hot or cold spots within your home. It helps the furnace or air conditioner maintain a consistent temperature throughout the house. This balance can lead to energy savings, as your system doesn’t have to work as hard to compensate for uneven temperatures.

Incorporating multiple return vents is an effective way to boost your home’s comfort and energy efficiency, leading to long-term cost savings and enhanced indoor air quality.

How to Prevent Filter Bending

It can be frustrating when your AC filter keeps bending, causing poor air quality and inefficient cooling. Luckily, there are simple ways to prevent this from happening. One solution is to install a filter support bracket, which provides additional support to keep the filter in place.

Another option is to regularly clean or replace the filter, as a dirty or clogged filter can be more susceptible to bending. Additionally, it’s important to make sure the filter is properly sized and fits snugly in the filter slot. Taking these precautions can not only prevent filter bending but also improve the overall performance and lifespan of your air conditioning system.

For those considering alternatives to low-end filters, you might want to stick to cheap fiberglass throwaway filters for their cost-effectiveness and convenience. However, if you’re ready to invest in better performance, consider upgrading to a 4″ or 5″ media filter. These filters typically offer enhanced air quality and efficiency, which can be beneficial for both your system’s longevity and your indoor air environment.

By combining regular maintenance with the right filter choice, you can ensure optimal air conditioning performance and potentially extend the life of your system.

Does a UV Light Installed Before an HVAC Filter Help with Filtration?

Installing a UV light before your HVAC filter can indeed enhance your home’s air quality but not in the way traditional filters do. Here’s a breakdown of how it works:

- UV Light Functionality: UV lights are effective at neutralizing bacteria, mold, and other pathogens present in the air. They target the DNA of these microorganisms, effectively killing or deactivating them, to prevent them from circulating throughout your home.

- Limitations on Airborne Particles: While UV lights are excellent at managing microorganisms, they do not physically remove dust, pollen, or other airborne particles from the air. This is why your HVAC system will still need a quality filter to trap these particles.

- Filter Compatibility: It’s important to choose the right type of filter to ensure optimal air circulation through your HVAC system. Filters with a high MERV rating, such as MERV 7 or 9, might restrict airflow unless you have sufficient return airflow, like dual filtered returns, to prevent filter bending or bowing.

Adding a UV light to your HVAC system can boost its ability to reduce harmful microorganisms, but it should be used in conjunction with a proper filter to capture larger air pollutants.

So don’t let a bent filter give you the blues – take proactive measures to keep your AC running smoothly!

Regular Cleaning and Maintenance

When it comes to maintaining a healthy and efficient HVAC system, regular cleaning and maintenance are key. One particular issue that can arise is filter bending, which can restrict airflow and put a strain on your system. To prevent this from happening, it’s important to check and change your filters regularly, as clogged or dirty filters can cause them to bend under the pressure.

Additionally, make sure to use high-quality filters that are appropriate for your specific system, and avoid stacking or doubling up filters as this can also cause them to bend. By staying on top of your filter maintenance and using proper care, you can keep your system running smoothly and avoid potential problems down the line.

Proper Alignment and Placement

As a pool owner, proper alignment and placement of your pool filter is crucial in ensuring its efficiency and longevity. One common issue that arises is filter bending, which can lead to leaks, cracks, and ultimately, the need for replacement. To prevent filter bending, experts recommend securing the filter tightly in the correct position with the appropriate tools.

Additionally, checking for any potential obstacles or uneven surfaces that may cause stress on the filter can also help prevent bending. By taking the necessary precautions and regularly inspecting your filter, you can save yourself from the costly and inconvenient consequences of filter bending. Remember, prevention is always better than replacement!

Add Additional Support for Your Filter

If you’re a photographer or videographer, it’s likely that you’ve encountered a filter bending or drooping issue at some point. This can be especially frustrating when you’re trying to capture the perfect shot and your filter isn’t staying in place, resulting in blurry or distorted images. To prevent filter bending, consider adding additional support to your filter.

One way to do this is by using a filter holder system that attaches directly to your lens and provides a sturdy base for your filter. Alternatively, you can invest in a filter clamp that attaches directly to your filter and secures it tightly to your lens. By adding this additional support, you can ensure that your filter stays in place and that your images turn out sharp and clear.

Don’t let filter bending ruin your shots – take the necessary steps to prevent it before it happens.

How Do Additional Returns Affect Air Flow and Filter Performance in HVAC Systems?

Adding extra return air ducts to an HVAC system can significantly enhance both air flow efficiency and filter performance. Here’s how:

Enhanced Air Flow

- Increased Air Volume: Introducing additional return ducts allows the system to draw in more air. This increase in volume helps meet the system’s maximum cubic feet per minute (CFM) potential, delivering more efficient heating or cooling.

- Reduced Air Velocity: With a larger surface area for air intake, the velocity through each duct decreases. Lower air speeds can minimize noise and wear on the ductwork, leading to a quieter and more durable HVAC system.

Improved Filter Performance

- Greater Filter Surface Area: More return ducts mean more space to accommodate filters. This added surface area can prevent filters from being easily overwhelmed by dust and debris, extending their lifespan and enhancing their performance.

- Better Air Quality: A system with optimized filter performance can more effectively trap pollutants and allergens. The result is cleaner, healthier air circulating throughout your home, providing a better overall indoor climate.

Implementing additional returns can transform the efficiency of your HVAC system, making it not only more effective but also potentially more cost-effective by reducing energy consumption and prolonging system life.

Does Installing a UV Light Before the Filter Improve Filtration?

Yes, installing a UV light before the filter can enhance filtration, but let’s look at how it works and what considerations you should keep in mind.

How UV Lights Work

UV light systems are designed to kill bacteria, mold spores, and viruses that might circulate through your HVAC system. When placed before the filter, these lights sanitize the air by breaking down the DNA of microorganisms, rendering them inactive.

Benefits of UV Light Installation

- Enhanced Air Quality: By neutralizing pathogens, UV lights prevent these microorganisms from reaching your living spaces, thereby improving overall air quality.

- Extending Filter Life: Since UV lights reduce the volume of living particles reaching the filter, the filter can focus more on capturing dust and other particulates. This potentially extends the filter’s life.

Important Considerations

- Filter Ratings: Choose an appropriate filter with a suitable MERV (Minimum Efficiency Reporting Value) rating. Filters with higher MERV ratings capture smaller particles but may restrict airflow. In some cases, more than one return filter might be necessary to maintain efficient airflow without damaging the filters.

- System Compatibility: It’s critical to ensure your HVAC system is compatible and can handle the integration of a UV light system without impairing airflow or efficiency.

In summary, while a UV light can improve the filtration of airborne contaminants by destroying biological particles before they reach the filter, optimizing its efficacy requires careful selection of compatible filter ratings and consideration of your system’s airflow needs.

When to Replace Your Filter

If you’ve noticed that your AC filter keeps bending, it’s likely time to replace it. A bent filter won’t be as effective at filtering out dust and debris from the air, which means your AC system will have to work harder to keep your home cool. A dirty or clogged filter can also lead to poor indoor air quality and potentially cause health issues, particularly if you have allergies or respiratory problems.

To ensure your AC system is running efficiently and that your home’s air is clean and healthy, it’s important to replace your filter regularly. Most manufacturers recommend replacing your filter every one to three months, depending on usage and environmental factors. Regular filter changes can also help prolong the life of your AC system by reducing wear and tear on its components.

So if you’ve noticed that your filter is bowing or bending, don’t wait to replace it – your home and your AC system will thank you!

Understanding the MERV Rating System for Filters

The Minimum Efficiency Reporting Value (MERV) is a standardized system that measures the effectiveness of air filters. It gauges how efficiently a filter can remove particles from the air, which can range from dust and pollen to mold spores and even certain bacteria. The MERV rating helps consumers and professionals choose the appropriate filter for their needs, balancing between air quality, airflow, and cost.

MERV Rating Scale:

- MERV 1-4: These filters offer basic filtration and are typically used in residential settings. They can capture large particles like dust and pollen but may not be suitable for individuals with allergies or respiratory concerns.

- MERV 5-8: Generally used in commercial or residential buildings, these filters provide a reasonable improvement in air quality, filtering finer particles such as mold spores and dust mite debris.

- MERV 9-12: These filters are more efficient and suitable for environments requiring cleaner air, such as hospitals or laboratories. They can capture lead dust and some bacteria, reducing allergens significantly.

- MERV 13-16: Approaching HEPA-like filtration, these filters are highly efficient at removing very fine particles, including smoke, bacteria, and certain viruses. They are often used in settings where air quality is of utmost importance.

- MERV 17-20: Although not typical for residential use, ratings in this range refer to HEPA (High-Efficiency Particulate Air) filters. These filters capture 99.97% of particles as small as 0.3 microns, providing the highest air purification available in commercial settings.

Comparison with Other Rating Systems

While MERV is widely accepted and used, other rating systems exist, such as:

- HEPA: Focuses specifically on extremely high filtration levels. HEPA filters work at a much finer level than traditional MERV filters.

- FPR (Filter Performance Rating): This is used by some companies to rate their filters based on a color-coded scale and offers a different perspective on filter performance, typically focusing on factors like dust-holding capacity and particle efficiency.

- MPR (Microparticle Performance Rating): Developed by 3M, MPR rates filters based on their ability to capture particles smaller than 1 micron, providing an alternative view of filter performance that complements MERV ratings.

3. Choosing the Right Filter

Selecting the right filter involves considering your specific air quality needs against your HVAC system’s capabilities. Higher MERV ratings equate to better filtration but may reduce airflow if your system isn’t designed to handle the increased restriction. Always check your system’s specifications and consult professionals if necessary to ensure optimal performance and air quality.

Understanding HVAC Filter Grades and Their Categorization

When choosing an HVAC filter, it’s important to understand the different grades available and how they are categorized. Filters are primarily rated using the Minimum Efficiency Reporting Value (MERV) scale. This system helps to measure the effectiveness of HVAC filters in trapping particles.

MERV Ratings Explained

- Low-Efficiency Filters (MERV 1-4):

These filters are basic and inexpensive, typically used for minimal air filtration. They’re best for protecting HVAC equipment rather than improving indoor air quality. - Moderate-Efficiency Filters (MERV 5-8):

A step up from the low-efficiency filters, these offer better particle capture for common allergens like dust and pollen, making them suitable for most homes. - High-Efficiency Filters (MERV 9-12):

These filters capture finer particles such as mold spores and other small contaminants. They’re ideal for households with pets or allergies. - Highest-Efficiency Filters (MERV 13-16):

Approaching the HEPA standard, these filters can trap bacteria and smoke particles. They are often used in settings requiring comprehensive air quality control, like hospitals. - HEPA Filters (Beyond MERV 16):

While not technically part of the MERV scale, HEPA filters represent the highest level of filtration, capable of trapping even the smallest airborne particles. They’re used in environments where clean air is critical.

Choosing the Right Filter

Selecting the right filter depends on your specific needs:

- For general home use, a MERV 7-8 is typically sufficient.

- Those with allergies might opt for a MERV 11-12 filter.

- If you’re seeking the highest level of air purification, consider HEPA-rated filters.

Understanding these categories ensures you choose the best filter for your HVAC system while enhancing air quality to suit your environment.

Signs of Wear and Tear

As homeowners, we must ensure our air filters are functioning properly and not putting our families’ health at risk. Signs of wear and tear on the filter usually indicate that it needs replacement. If you observe the filter appears dirty or clogged, it’s time to take immediate action and replace it.

Dirty filters can reduce your home’s indoor air quality, causing allergies, asthma, and respiratory problems. Another warning sign is when the air filter makes strange noises or rattling sounds once installed. That could indicate that the filter is not fitting properly and that air can bypass, reducing its efficiency.

Remember, replacing your air filter every 3 months is good practice and helps keep your home’s air clean and fresh.

Consequences of Exceeding Recommended Static Pressure in a Variable Speed ECM Blower

When it comes to managing the static pressure in a variable speed ECM (Electronically Commutated Motor) blower, adhering to manufacturer guidelines is crucial. Exceeding these limits can lead to several detrimental outcomes:

- Reduced Motor Lifespan

Operating above the recommended static pressure range, typically around 0.7-0.8 inches of water column (“”WC), can significantly shorten the lifetime of your ECM blower. The motor is forced to work harder, which can accelerate wear and tear. - Increased Energy Consumption

As the blower struggles to maintain adequate airflow under higher pressure, it draws more power. This inefficiency results in higher energy bills, negating the energy-saving benefits that ECM blowers are known for over traditional PSC (Permanent Split Capacitor) motors. - Overheating and Failure Risk

Continuous operation under excessive pressure can cause the motor to overheat, leading to potential failure. This not only disrupts system performance but can also result in costly repairs or replacements. - Decreased System Performance

High static pressure hampers the blower’s ability to circulate air efficiently throughout the HVAC system. This can lead to uneven heating or cooling, making it challenging for the system to maintain desired indoor temperatures.

To ensure optimal performance and longevity of your ECM blower, regular maintenance and monitoring of static pressure levels are essential. Ensuring ducts are clean and free from blockages can help maintain manageable pressure levels and prolong the efficient operation of your HVAC system.

The Importance of Multiple Filtered Returns in an HVAC System

Having multiple filtered returns in an HVAC system offers several key benefits that enhance both the functionality and efficiency of the heating and cooling processes. Here’s a closer look at why this setup is advantageous:

1. Improved Air Flow

When an HVAC system has more than one filtered return, it provides greater surface area for air entry. This configuration supports a higher cubic feet per minute (CFM) of airflow. By distributing the air intake across multiple points, the system experiences a smoother and more consistent airflow, which is crucial for maintaining efficient heating and cooling.

2. Reduced Air Velocity

With multiple returns, the air velocity inside the ductwork is significantly decreased. Lower air speed results in quieter operation and reduces the risk of wear and tear on the system components. The slower movement of air allows for a more thorough exchange of air, improving the system’s overall performance and longevity.

3. Enhanced Filtration and Air Quality

With more filtered returns, there is an increased filtering capacity. This setup ensures that contaminants like dust, pollen, and other particulates are captured more effectively. Improved air quality is beneficial not only for the health of the occupants but also for maintaining clean and efficient HVAC operation.

4. Better Temperature Distribution

Multiple returns help in achieving more uniform temperature distribution throughout a building. By pulling air from different areas, the system can more effectively balance the temperature, reducing hot or cold spots and improving comfort levels for all occupants.

integrating multiple filtered returns in an HVAC system significantly boosts its performance, efficiency, and lifespan while ensuring a healthier indoor environment. Through enhanced airflow, reduced velocity, and improved air quality, this configuration is essential for optimal HVAC operation.

Understanding the Impact of Higher-Rated Filters on Your HVAC System

When considering upgrading to higher-rated filters for your HVAC system, it’s essential to weigh the benefits against potential drawbacks. Here’s what you need to know:

Pros of Higher-Rated Filters

- Enhanced Air Quality: Filters with higher ratings are designed to capture smaller particles, helping to reduce indoor allergens, dust, and pollutants. This can result in better air quality and a healthier home environment.

Cons of Higher-Rated Filters

- Airflow Restriction: Higher-rated filters often have denser media, which can restrict airflow. For some systems, this could mean the airflow is too limited, leading to inefficiencies. If your system requires substantial airflow, a more restrictive filter might impede its performance.

- Potential for Filter Damage: If the airflow is not adequately managed, the filters might bend or bow. This is especially true if the system is not equipped with multiple returns to distribute airflow evenly.

Recommendations

- Evaluate Your System’s Needs: Before making a switch to a higher-rated filter, assess whether your HVAC system can handle the change without compromising airflow. This often requires understanding the specific requirements of your furnace.

- Consider Filter Alternatives: You might need to install multiple filtered return air ducts to accommodate the increased filtration without hindering performance. This adjustment can help maintain the efficiency of your system while still benefiting from improved air quality.

Ultimately, higher-rated filters are not inherently a waste of money. However, it’s crucial to ensure compatibility with your system to avoid unnecessary expenses and potential damage.

Understanding MERV Filter Ratings

When it comes to air filters, the Minimum Efficiency Reporting Value (MERV) is the standard used to assess their effectiveness. The MERV scale ranges from 1 to 16, with each level indicating the filter’s ability to capture particles of varying sizes.

1. Low-Grade Filters (MERV 1-4):

- These filters are the most economical and are often found in basic household settings.

- They offer minimal filtration, capturing larger particles like dust and pollen.

2. Moderate Efficiency Filters (MERV 5-8):

- Suitable for residential and light commercial use.

- They provide better filtration, capable of trapping smaller allergens like mold spores.

3. High-Efficiency Filters (MERV 9-12):

- Ideal for homes with pets or residents who suffer from allergies.

- These filters catch even finer particles, such as pet dander and dust mite debris.

4. Superior Efficiency Filters (MERV 13-16):

- Often used in hospitals and commercial buildings where air quality is crucial.

- These high-grade filters effectively capture bacteria, smoke, and even some viruses.

HEPA Filters:

- While technically not covered by the MERV rating, HEPA filters are often equated to MERV 16.

- Known for their exceptional ability to filter out the tiniest of particles, they are used in environments requiring the highest air quality standards.

Choosing the right filter depends on your specific air quality needs, ranging from basic protection to advanced filtration for health and safety.

Conclusion

After all of our research and testing, we’ve come to the conclusion that the reason your AC filter keeps bending is due to the sheer force of your home’s coolness. Your air conditioning is just too powerful for its own good! So, if you want to straighten out your filter, maybe it’s time to turn down the cool factor and give your poor filter a break.

FAQs

What could cause my AC filter to keep bending?

There are several possible reasons for this, including airflow issues, improper installation, and dirty or clogged filters. It’s important to address the root cause in order to prevent further damage to your AC system.

How often should I change my AC filter?

It’s recommended to change your AC filter every 1-3 months, depending on usage. If your filter is bending frequently, it may be a sign that it needs to be changed more frequently.

Can a dirty AC filter cause my system to malfunction?

Yes, a dirty or clogged AC filter can cause a variety of issues, including reduced airflow, decreased efficiency, and even system failure. It’s important to keep your filter clean and change it regularly in order to avoid these problems.

What steps can I take to prevent my AC filter from bending?

First, make sure you are using the correct size and type of filter for your system. Second, ensure that the filter is installed properly and securely. Lastly, consider installing a filter support frame or using a higher quality filter that is less likely to bend under pressure.

HVAC BTU Size

The HVAC system is utilizing a filter that measures 20 by 25 inches. Additionally, it is equipped with equipment that has a heating capacity of 85,000 BTUs.