Have you ever felt frustrated with your air conditioner unit not providing as much cold air as it used to, or not even turning on altogether? The culprit may be with the compressor, a vital component responsible for the cooling process. It’s important to know how to check and test your air conditioner compressor to ensure it’s functioning properly. Imagine it like a heart in your air conditioner unit; if it’s not working, then the rest of the system won’t function as well.

In this blog post, we’ll guide you on testing your air conditioner compressor and diagnosing any issues to keep your home cool and comfortable during the hottest days of the year.

Diagnostic Tools

Are you experiencing issues with your air conditioner compressor and wondering how to test it? There are some simple diagnostic tools you can use to identify the problem. The first step is to check the electrical connections and ensure they are not loose or damaged. Then, you can use a multimeter to see if there is power flowing to the compressor.

If the power is flowing but the compressor is not turning on, it could be an issue with the capacitor. You can also check the refrigerant levels to see if they are low and causing the compressor to malfunction. If none of these solutions seem to fix the issue, it may be time to bring in a professional for a more thorough diagnosis and repair.

Remember to always follow safety precautions when working with electrical components and consult the user manual for specific instructions for your air conditioning unit. By using these diagnostic tools, you can save yourself time and money by identifying and addressing the issue with your air conditioner compressor.

Multimeter/Capacitor Tester

As a mechanic or an electronics enthusiast, it is essential to have the right diagnostic tools in your toolbox, and one of the most crucial tools is the multimeter/capacitor tester. This tool helps you accurately measure electrical values such as voltage, current, and resistance. Additionally, a capacitor tester will help you determine if a capacitor is faulty or not.

Faulty capacitors can lead to several issues in electronic devices, such as overheating and power supply problems. With a multimeter/capacitor tester, you can quickly identify problems in a circuit, helping you save time and effort in troubleshooting. The market is full of various brands and models, each with its unique features and capabilities.

Remember to choose a tester that meets your specific needs and is within your budget. So, if you haven’t already invested in a multimeter/capacitor tester, make sure to add it to your toolkit for fast, accurate, and reliable electrical diagnostics.

Thermometer/Hygrometer

A thermometer/hygrometer is a critical diagnostic tool used to measure two important environmental factors that can impact human comfort and well-being – temperature and humidity. These tools are essential in monitoring the indoor or outdoor environment and ensuring optimal living conditions for people and pets. With advanced features like digital displays, wireless connectivity, and alert systems, modern thermometers and hygrometers are highly accurate and reliable.

They can detect even the slightest changes in temperature and humidity levels, providing timely insights to prevent mold growth, condensation, and other environmental hazards. Whether it’s for personal use or commercial applications like manufacturing and air conditioning, having a thermometer/hygrometer at hand is crucial for creating a comfortable and healthy living environment. With its precise measurement capabilities, you can adjust the temperature and humidity levels for optimal comfort – no more shivering or sweating excessively.

In summary, a thermometer/hygrometer is an essential tool for anyone looking to monitor the impact of temperature and humidity on their health, comfort, and well-being.

Preparing for Testing

When it comes to testing your air conditioner compressor, it’s important to first prepare properly. Before getting started, make sure you disconnect the power to your system and locate the compressor in your unit. Once you’ve found it, remove the compressor cover and inspect it for any obvious signs of damage or wear.

Check the wiring connections for any signs of corrosion or loose connections. Next, you’ll want to test the capacitors and the start relay by using a multimeter. This will help you determine if there are any electrical issues that need to be addressed.

Finally, you can test the compressor itself by using an amp clamp meter to measure the electrical current running through the system. By following these steps, you’ll be able to properly diagnose any issues with your air conditioner compressor and ensure that it’s running smoothly for the season ahead.

Turn off Power

When preparing to test electrical equipment or wires, it’s crucial to turn off the power source. This may seem obvious, but it’s worth mentioning as it could save your life. Never assume that a device is off just because it’s not turned on.

Always unplug the device, switch off the circuit breaker, or remove the fuse to ensure the power is completely turned off. Double-check the power switch or circuit breaker with a voltage tester. This test will guarantee that the power is off before starting any work.

If you’re not sure which switch or circuit breaker controls the power to the equipment, turn off ALL switches or breakers. Better to be safe than sorry. Electrical currents can cause severe harm or even death, so make sure you take the necessary precautions before beginning any electrical work.

Remove Access Panel

Preparing for testing your system involves certain steps, among them, removing the access panel. This allows you to access the internal components of the system and test them for proper functioning. Before you begin, it’s important to ensure that you have the necessary tools and equipment, such as a screwdriver and an anti-static wristband, to avoid damaging the system or affecting its performance.

Make sure to also disconnect the power supply and all peripherals before opening the access panel. Once you are ready, remove the screws that hold the panel in place and carefully slide it off, using caution not to tug on any cables or other components. With the access panel removed, you can now begin testing each component and verifying that everything is in working order.

Remember to take your time and be thorough, ensuring that your system is functioning optimally before closing it back up.

Locate Compressor and Capacitor

When it comes to preparing to test your compressor and capacitor, the first step is to locate them. Your compressor is typically located in the outdoor unit of your air conditioning system, while your capacitor is often found either inside the outdoor unit or inside your home near the air handler. It’s important to turn off the power to your air conditioning system before you begin any testing or maintenance.

Make sure to read the instructions for your specific unit and wear protective gear, such as gloves and safety glasses, to avoid injury. Once you’ve located your compressor and capacitor, you can begin testing them to ensure that they’re functioning properly. It’s always a good idea to consult a professional if you’re unsure about any steps in the process or if you don’t have any previous experience with air conditioning maintenance.

By taking the time to properly prepare and locate your compressor and capacitor, you can help ensure the longevity and effectiveness of your air conditioning system.

Testing the Compressor

As the beating heart of your air conditioner, the compressor is essential for producing cool air and keeping your home comfortable. However, like any other mechanical component, it can suffer from wear and tear over time, leading to problems down the line. If you suspect that your compressor may be on the fritz, a quick test can help you diagnose the problem and take action before it’s too late.

Firstly, check the power supply to ensure that the compressor is getting the electricity it needs to function. You can also check for physical signs of damage, such as leaks or bent fins. If everything looks fine, you can test the compressor itself by using a multimeter to measure its resistance.

A reading of zero indicates a short circuit, while a high resistance reading suggests an open circuit. If you’re unsure how to test your air conditioner compressor, contacting a professional is always a good idea. With regular maintenance and attention, you can keep your compressor running smoothly and ensure that your home stays cool and comfortable all year round.

Check for Power

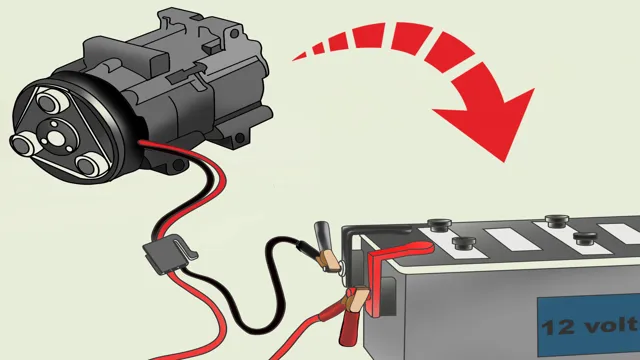

When troubleshooting a refrigerator that’s not cooling properly, it’s important to check if the compressor is working properly. This can be done by testing for power. Make sure the refrigerator is plugged in and the outlet is working by testing it with another appliance.

Then, locate the compressor and unplug it. Using a multimeter, check the power supply to the compressor by placing the probes on the prongs of the compressor plug. If the multimeter reads zero, then there is no power supply to the compressor and further investigation is needed.

If the multimeter shows power, then the compressor may be faulty and need to be replaced. Testing the compressor’s power supply is an essential step in diagnosing the issue and resolving it quickly.

Check for Continuity

When troubleshooting your air conditioning system, it’s important to test the compressor. One way to do this is to check for continuity. Continuity refers to the presence of an unbroken path for electrical current to flow.

To test for continuity, you will need a multimeter. Set your multimeter to “ohms” and touch one probe to the shaft of the compressor and the other to one of the pins on the compressor terminals. The multimeter should read between 3 and 12 ohms.

If it reads 0, there is a short circuit in the compressor and it will need to be replaced. If it reads infinity, there is an open circuit and the compressor will also need to be replaced. Checking for continuity is an important step in diagnosing any potential issues with your air conditioning system.

Check for Resistance

When it comes to testing the compressor, it’s essential to check for resistance. Resistance is a measure of how much force is opposing the flow of electricity. It can be caused by multiple factors, such as a damaged compressor or a faulty capacitor.

To test the compressor for resistance, first, turn off the power supply to the unit. Then, use a multimeter to measure the resistance of the compressor terminals. The meter should show a reading between three and four ohms.

If the reading is lower or higher than this range, it indicates a problem with the compressor. In this case, it’s best to call a professional technician for assistance. Testing the compressor for resistance is crucial to ensure that it’s functioning correctly and capable of providing optimal cooling performance.

Conclusion

Testing your air conditioner compressor is like taking your car on a test drive before a road trip. Just like you wouldn’t hit the highway without ensuring your vehicle is in top shape, you shouldn’t let your AC system fail when you need it most. So give your compressor the attention it deserves and take the time to test it before the summer heat arrives.

Trust us, you’ll thank yourself later when you’re lounging comfortably in a cool and refreshing home.”

FAQs

What are the signs that the air conditioner compressor is failing?

The signs of a failing air conditioner compressor include poor cooling performance, unusual noises from the unit, and an overheated compressor.

How can I test if my air conditioner compressor is working properly?

To test if your air conditioner compressor is working properly, you can check if the unit is properly cooling the room, listen for any unusual noises or vibrations coming from the unit, and look for any signs of leaks or damage to the compressor.

How often should I have my air conditioner compressor checked?

It is recommended to have your air conditioner compressor checked annually by a professional technician to ensure that it is working properly and to catch any potential problems before they become major issues.

What maintenance should I perform on my air conditioner compressor to keep it in good condition?

To keep your air conditioner compressor in good condition, you should clean or replace the air filters regularly, keep the area around the unit clear of debris and vegetation, and schedule annual maintenance checkups with a professional technician.